Viona Magnetics

Viona Magnetics Request A Quote

Hicksville, NYViona Magnetics is a leading provider of advanced magnet assemblies, offering comprehensive solutions to meet diverse industrial needs. With a strong focus on innovation, quality, and customer satisfaction, Viona Magnetics has established itself as a trusted partner in the field of magnet technology. Product Offerings: Viona Magnetics specializes in the design, manufacturing, and supply of high-quality magnet assemblies. These magnet assemblies encompass a wide range of applications, serving various industries including automotive, aerospace, electronics, healthcare, energy, and more. The company's product portfolio includes: 1. Permanent Magnet Assemblies: Viona Magnetics excels in creating magnet assemblies utilizing permanent magnets such as neodymium (NdFeB), samarium cobalt (SmCo), and ferrite magnets. These assemblies are customized to meet specific requirements, incorporating magnets in various shapes, sizes, and configurations. 2. Magnetic Assemblies for Motors and Generators: Viona Magnetics offers magnet assemblies designed for electric motors and generators, enabling efficient power generation and motion control. These assemblies are engineered to deliver optimum performance, high torque, and exceptional reliability. 3. Magnetic Sensors and Actuators: Viona Magnetics provides magnet assemblies for sensing and actuation applications. These assemblies are employed in diverse industries, including robotics, automation, and medical devices, to enable precise and responsive motion control. 4. Magnetic Separators and Filters: The company manufactures magnet assemblies for separation and filtration purposes. These assemblies are utilized in industries such as mining, food processing, and recycling, to efficiently remove unwanted magnetic contaminants from materials. Service Capabilities: Viona Magnetics is not just a product supplier; it is a comprehensive solutions provider. The company offers a range of services to support its customers throughout the entire product lifecycle: 1. Engineering and Design: Viona Magnetics has a dedicated team of engineers who work closely with clients to understand their specific requirements. They provide expert guidance in designing magnet assemblies that meet performance, efficiency, and cost objectives. 2. Prototyping and Testing: The company offers prototyping services, allowing customers to validate their designs before proceeding to full-scale production. Viona Magnetics conducts rigorous testing to ensure that the magnet assemblies meet the highest quality standards. 3. Manufacturing and Production: Viona Magnetics operates state-of-the-art manufacturing facilities equipped with advanced machinery and technologies. The company leverages its expertise in magnet assembly production to deliver products with precision, consistency, and adherence to tight tolerances. 4. Quality Control: Quality is of paramount importance to Viona Magnetics. The company employs stringent quality control measures at every stage of the manufacturing process. Through rigorous testing and inspection, they ensure that the magnet assemblies meet or exceed customer expectations. 5. Customization and Tailoring: Viona Magnetics understands that each customer's requirements are unique. Therefore, the company offers customization options to tailor magnet assemblies according to specific needs, including magnet material selection, shape, size, and magnetic field strength. 6. Technical Support and After-sales Service: Viona Magnetics provides comprehensive technical support to its customers. The company's team of experts offers guidance, troubleshooting assistance, and after-sales service to ensure that the magnet assemblies deliver optimal performance and longevity. By combining cutting-edge technology, expertise in magnetism, and a customer-centric approach, Viona Magnetics has established itself as a leading provider of magnet assemblies. The company continues to innovate and invest in research and development, pushing the boundaries of magnet technology to meet the evolving needs of its customers across industries.

Alloy Suppliers

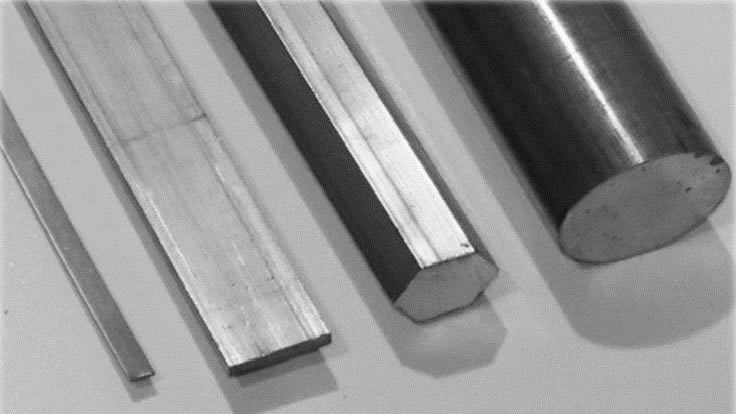

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

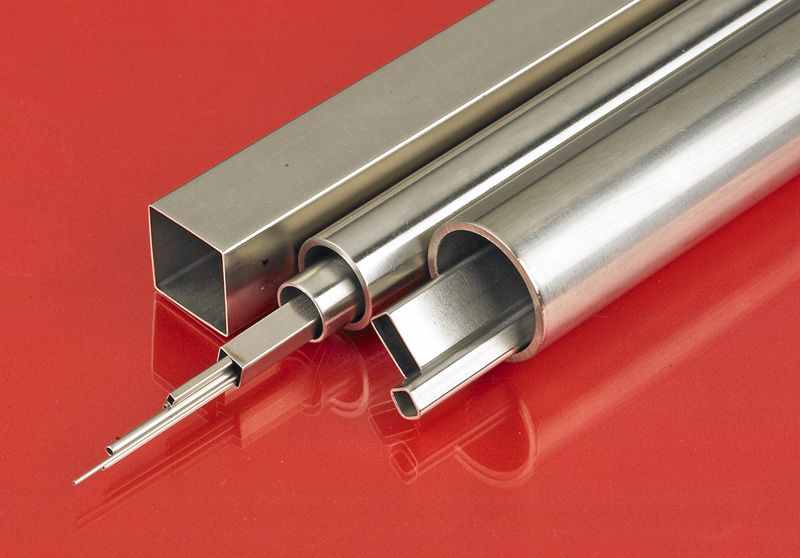

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

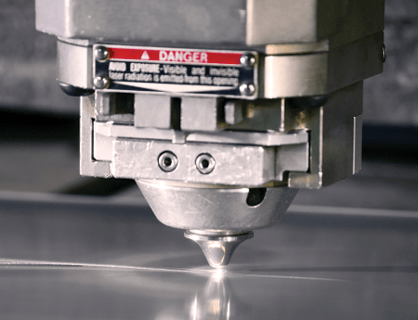

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services