Ceramic magnets, also called ferrite core magnets, are hard and permanent magnets with low costs. The composition of ceramic magnets includes iron oxide and strontium carbonate. They exhibit medium magnetic strength and can be used at fairly high temperatures. Read More…

Founded in 1895, Arnold Magnetic Technologies is a leading global manufacturer of high performance permanent magnets, electromagnetics, magnetic assemblies, and precision thin metals.

Our customers know they can trust us to provide them with the best magnets in the industry. We supply magnets from only the best manufacturers in the world. We will not offer substandard products or anything that is not the most cost-effective solution.

CMS Magnetics excels as a leading magnet supplier, offering a vast array of high-quality neodymium, hard ferrite, SmCo, and AlNiCo magnets. We also provide diverse magnetic assemblies like pot magnets, channel magnets, and magnetic lifters, tailored for various applications. Our commitment to excellence is backed by a 100% customer satisfaction guarantee and a money-back promise. We accept custom ...

Since 1942, Eriez has been specializing in separation technology for a variety of industries. Eriez designs, develops, and manufactures magnets and related products. Eriez has 8 locations addition to their headquarters in Pennsylvania, making it convenient to ship their products all over the world. With proper care, Eriez magnet products can last a lifetime and not lose strength. Eriez offers...

At TyTek Industries, we are experts in manufacturing magnetic components. Our magnetics catalog include magnetic assembly, alnico magnets, rare earth magnets, and many more. It is our team’s mission to always draw on our strengths and experience to ensure the very best service and quality for our customers. For more information, visit our website or call today!

More Ceramic Magnet Manufacturers

What are Ceramic Magnets?

Ceramic magnets are resistant to oxidation and typically do not require additional protective finishes or coatings. In addition, they are resistant to corrosion and easy to magnetize. This makes them a popular choice for most consumers in industrial, commercial, and technical applications.

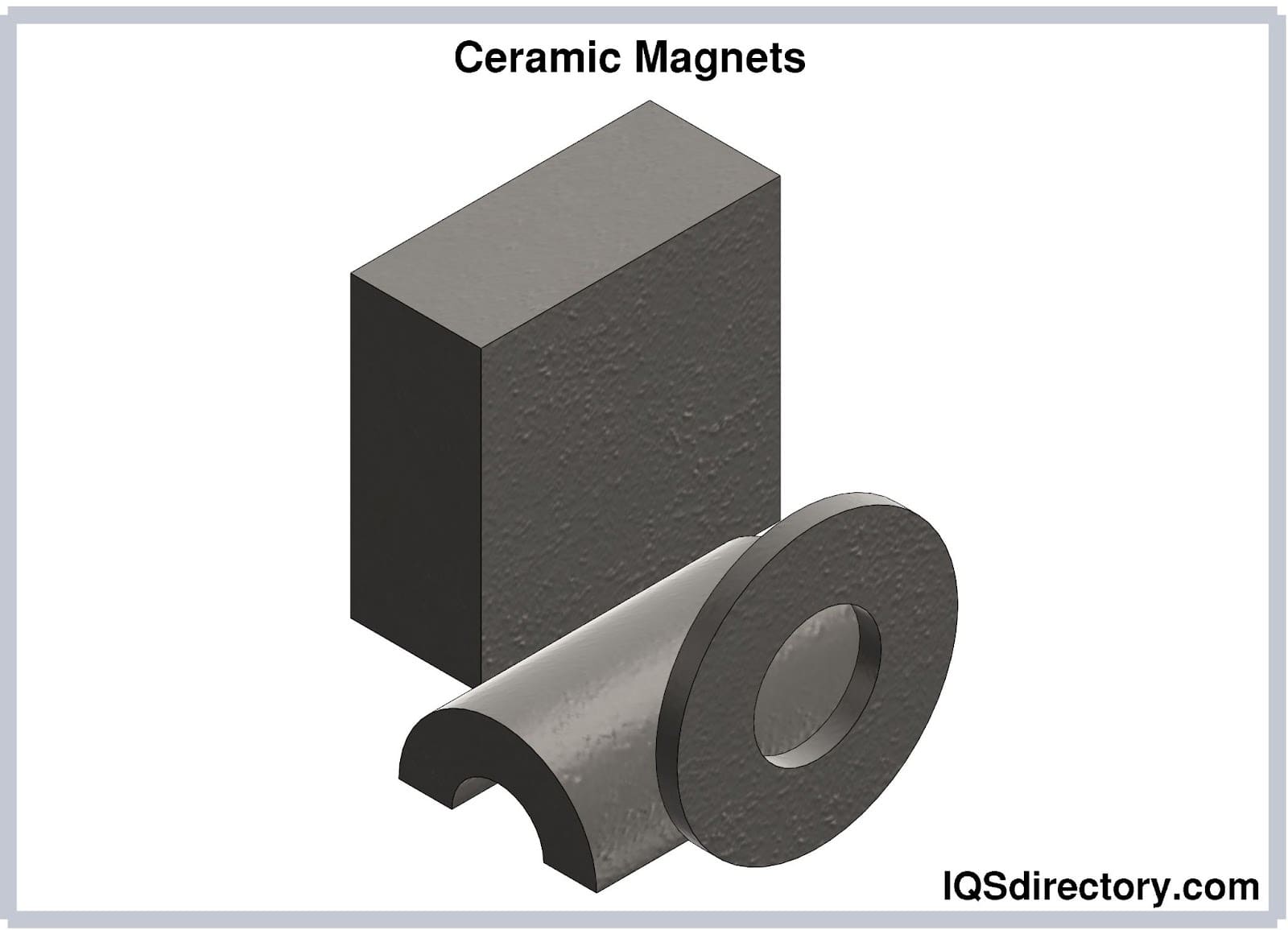

A wide range of shapes is available for these magnets, including block (rectangular and square), disc, round cup, and ring magnets.

Chemical Composition of Ceramic Magnets

Ceramic magnets are a type of permanent magnet with a composition of the chemical compound ferrite, composed of ceramic materials and iron oxide (Fe2O3). The chemical composition of ceramic magnets is SrO-6(Fe2O3).

Ceramic magnets are made from the following raw materials: iron oxide and strontium. Every ceramic magnet has a composition of 10% strontium carbonate and 90% iron oxide. These raw materials are economically available in abundance.

The Manufacturing Method of Ceramic Magnets

Ceramic magnets are produced by calcining a mixture of strontium carbonate and iron oxide to form a metallic oxide. A multiple-stage milling operation reduces the material that has been calcined to small particle size.

Two methods are then used to compact the powder in a die. In the first method, the compaction of the powder is done dry. This will develop an isotropic magnet that exhibits weaker magnetic properties but with better tolerances in dimensions. Most often, a magnet that is dry pressed does not require finishing grinding.

In the second method, the powder is mixed with water to form a slurry. A die is used to compact the die in a magnetic field. The field that has been applied creates an anisotropic magnet exhibiting superior magnetic properties, but it usually requires finish grinding.

To achieve the individual particles’ final fusion, the parts that have been compacted to approximate the finished geometry are sintered at high temperatures. Finally, diamond abrasives are used to achieve the final shaping.

Types of Ceramic Magnets

The different types of ceramic magnets include:

Ceramic Permanent Magnets

These are commonly seen small black magnets. The main raw materials that are used in the manufacture of these types of ceramic magnets are barium carbonate, iron oxide, or strontium carbonate. The residual magnetic field’s intensity increases after magnetization and can be maintained for a long time.

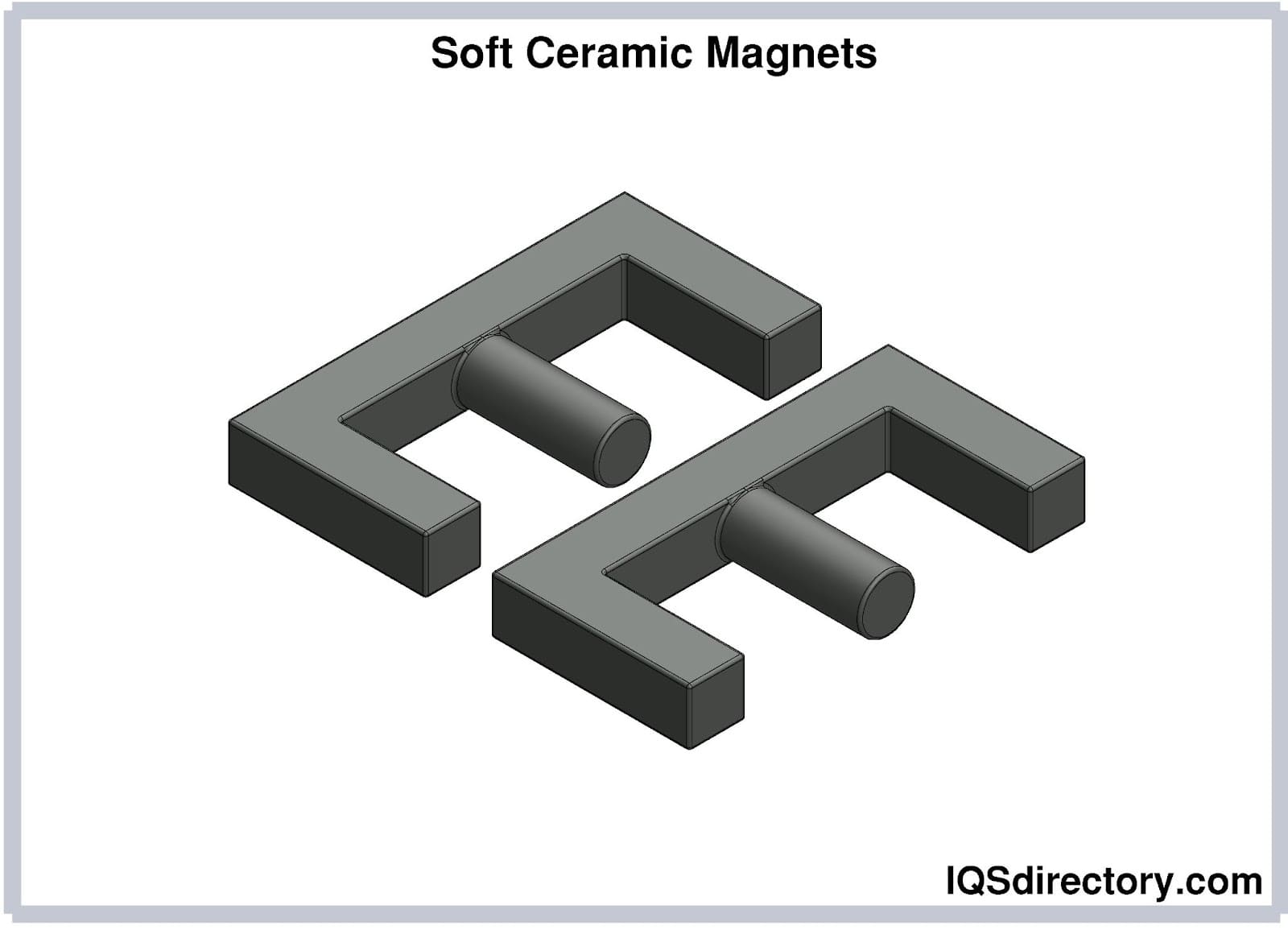

Soft Ceramic Magnets

These types of ceramic magnets are prepared by the sintering of ferric oxide and one or several metal oxides. The metal oxides include zinc oxide, strontium oxide, barium oxide, magnesium oxide, manganese oxide, nickel oxide, etc.

These types are called soft ceramic magnets because when the magnetic field disappears, the size of the residual magnetic field becomes small or almost non-existent. They are often utilized as choke coils or in intermediate transformers as the core. This is different from the permanent type ceramic magnets.

Gyromagnetic Ceramic Magnets

These are kinds of ferrite materials that exhibit gyromagnetic properties. Rotary magnetism of magnets is the phenomenon that planar polarized electromagnetic waves’ polarization surface rotates around the direction of propagation in the course of propagation.

This occurs in a specific direction in the material under the action of two perpendicular DC magnetic fields and magnetic fields of electromagnetic waves. Gyromagnetic ceramic magnets are mostly utilized in microwave communications.

Applications and Benefits of Ceramic Magnets

The different applications and benefits of ceramic magnets include:

Applications of Ceramic Magnets

- Magnetic assemblies designed for holding, lifting, retrieving, and separating

- Guitar pickups

- Breaks and clamps

- Relays

- Switches

- Motors and generators

- Eddy current devices

- Loudspeakers

- School projects

- Security systems

- Crafting projects

- Model making

- Science experiments

- Fridge magnets

Benefits of Ceramic Magnets

- Ceramic magnets are produced at low costs.

- Their intrinsic coercivity is much higher than that of Alnico magnets. This, in turn, makes them better at resisting demagnetization from external magnetic fields.

- Ceramic magnets exhibit high magnetic permeability, which makes them capable of storing stronger magnetic fields than metallic magnets.

- They are available in simple shapes because of the manufacturing process.

- Their service temperature is lower than that of Alnico.

- Ceramic magnets are lower energy products than Alnico magnets.

Choosing the Right Ceramic Magnets Manufacturer

To make sure you have the most productive outcome when purchasing Ceramic Magnets from a Ceramic Magnets Manufacturer, it is important to compare at least 6 Companies using our list of Ceramic Magnets manufacturers. Each Ceramic Magnets Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Ceramic Magnets company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Ceramic Magnets businesses with the same message.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services