Bar magnets are an essential component in various industries, from healthcare to energy production, electronics, transportation, and more. They are popularly known for their strength and ability to attract and repel other magnetic objects. In this article, we will discuss the creation, considerations regarding the creation and use, benefits, and applications of bar magnets. Read More…

Founded in 1895, Arnold Magnetic Technologies is a leading global manufacturer of high performance permanent magnets, electromagnetics, magnetic assemblies, and precision thin metals.

Our customers know they can trust us to provide them with the best magnets in the industry. We supply magnets from only the best manufacturers in the world. We will not offer substandard products or anything that is not the most cost-effective solution.

CMS Magnetics excels as a leading magnet supplier, offering a vast array of high-quality neodymium, hard ferrite, SmCo, and AlNiCo magnets. We also provide diverse magnetic assemblies like pot magnets, channel magnets, and magnetic lifters, tailored for various applications. Our commitment to excellence is backed by a 100% customer satisfaction guarantee and a money-back promise. We accept custom ...

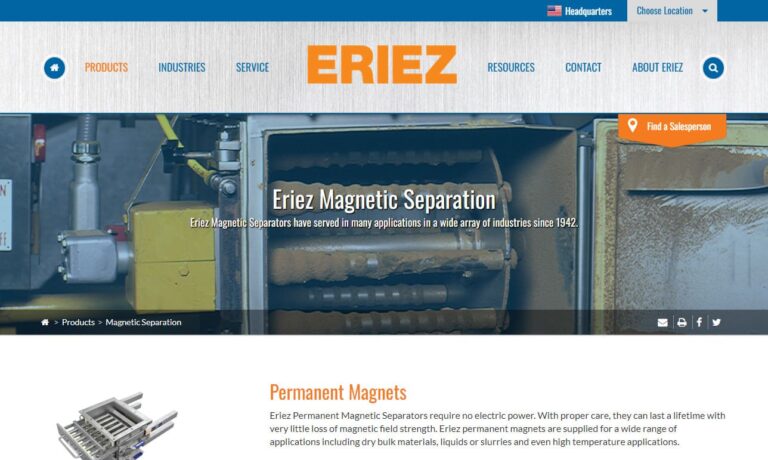

Since 1942, Eriez has been specializing in separation technology for a variety of industries. Eriez designs, develops, and manufactures magnets and related products. Eriez has 8 locations addition to their headquarters in Pennsylvania, making it convenient to ship their products all over the world. With proper care, Eriez magnet products can last a lifetime and not lose strength. Eriez offers...

At TyTek Industries, we are experts in manufacturing magnetic components. Our magnetics catalog include magnetic assembly, alnico magnets, rare earth magnets, and many more. It is our team’s mission to always draw on our strengths and experience to ensure the very best service and quality for our customers. For more information, visit our website or call today!

More Bar Magnet Manufacturers

Creating Bar Magnets

There are different processes involved in creating bar magnets, such as sintering, bonding, injection molding, and extrusion. Each of these methods and their specific application regarding bar magnets are explained below.

Sintering

Sintering is a common process used to create bar magnets from powdered metal. The process involves heating the powder until it fuses together to form a solid, dense magnet. This process is often used for creating neodymium magnets, which have a high strength-to-weight ratio and are commonly used in electric motors and generators.

Bonding

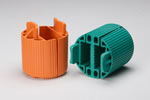

Bonding is a process used to create bar magnets by mixing magnetic powder with a binder material, such as plastic or rubber. The mixture is then molded into the desired shape and cured to create a solid magnet. Bonded magnets are often used in applications where high strength is not required, such as in audio speakers or sensors.

Injection Molding

Injection molding is a process used to create bar magnets by injecting magnetic material into a mold. The mold is then cooled and removed, leaving a solid magnet in the desired shape. This process is often used for creating small, intricate shapes, and is commonly used in the manufacture of magnetic sensors and other electronic components.

Extrusion

Extrusion is a process used to create bar magnets by forcing magnetic material through a die to create a specific shape. The material is then cooled and cut to size. This process is commonly used for creating magnetic strips , which are used in a variety of applications, ranging from refrigerator magnets to magnetic door seals.

Considerations Regarding Bar Magnets

The creation and use of bar magnets also come with potential considerations to take into account. For instance, strong magnetic fields found in bar magnets can pose health risks to people exposed to them, such as headaches, dizziness, and nausea. Additionally, these magnetic fields can interfere with electronic devices and equipment, leading to damage or failure. Meanwhile, the mining of rare-earth metals, which are vital in creating strong magnets, can have environmental impacts such as water and air pollution. However, it is essential to note that efforts are being made to reduce the environmental impact through responsible mining and recycling.

Benefits Provided by Bar Magnets

Bar magnets offer several benefits that make them an attractive choice for various applications.

To begin with, bar magnets have an excellent strength-to-weight ratio, meaning they can generate strong magnetic fields despite being relatively small and lightweight. This makes them ideal for use in applications where space is limited or weight is a concern. Next, bar magnets are durable and long-lasting. They can maintain their magnetic properties for decades, and they are not easily demagnetized or affected by external factors such as temperature or radiation.. Additionally, bar magnets are highly resistant to corrosion. They are commonly made of materials such as neodymium, which has excellent resistance to rust and other forms of corrosion. This makes them ideal for use in harsh environments, such as in marine applications or in the oil and gas industry.

Applications of Bar Magnets

Due to their benefits, applications of bar magnets are diverse and widespread and include:

Healthcare

In healthcare, bar magnets are used in MRI machines to create a magnetic field that produces images of the body's internal structures. They are also used in drug delivery systems to target specific areas of the body.

Electronics

In electronics, bar magnets are used in speakers, and hard drives. Bar magnets are also used in electric motors, which convert electrical energy into mechanical energy to drive machinery and equipment.

Construction and Infrastructure

In construction and infrastructure, bar magnets are used to reinforce concrete and detect underground utilities.

Transportation

In transportation, bar magnets are used in maglev trains, which use magnetic levitation to reduce friction, resulting in high speeds and efficiency. They are also used in hybrid and electric vehicles to power electric motors.

Energy Production

Bar magnets also play a crucial role in energy production, such as wind turbines, electric generators, and motors.

Marine Applications

Bar magnets are commonly used in marine applications due to their excellent resistance to corrosion. They are used in a variety of marine equipment, such as compasses, depth finders, and motors. Bar magnets are also used in offshore oil rigs to power motors and generators, and to control valves and other machinery.

Oil and Gas Industry

Bar magnets are also used in the oil and gas industry to help locate and extract oil and natural gas from the ground. They are used in equipment such as drilling rigs, magnetic survey tools, and magnetic filters. Bar magnets can also be used to prevent equipment from becoming contaminated with metal debris, which can damage machinery and cause downtime.

Choosing the Right Bar Magnet Supplier

To ensure you have the most positive outcome when purchasing bar magnets from a bar magnet supplier, it is important to compare several companies using our directory of bar magnet suppliers. Each bar magnet supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each bar magnet business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple bar magnet companies with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

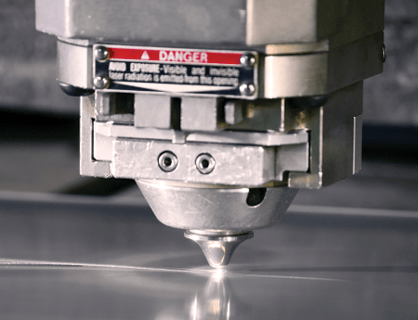

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services