The magnetic field is generated when the electric current passes through a wire, and the field dissipates when the current stops. The primary function of electromagnets is that they are used to lift metallic objects as well as being utilized in the design of many different machines and electronic systems. Read More…

Founded in 1895, Arnold Magnetic Technologies is a leading global manufacturer of high performance permanent magnets, electromagnetics, magnetic assemblies, and precision thin metals.

Our customers know they can trust us to provide them with the best magnets in the industry. We supply magnets from only the best manufacturers in the world. We will not offer substandard products or anything that is not the most cost-effective solution.

CMS Magnetics excels as a leading magnet supplier, offering a vast array of high-quality neodymium, hard ferrite, SmCo, and AlNiCo magnets. We also provide diverse magnetic assemblies like pot magnets, channel magnets, and magnetic lifters, tailored for various applications. Our commitment to excellence is backed by a 100% customer satisfaction guarantee and a money-back promise. We accept custom ...

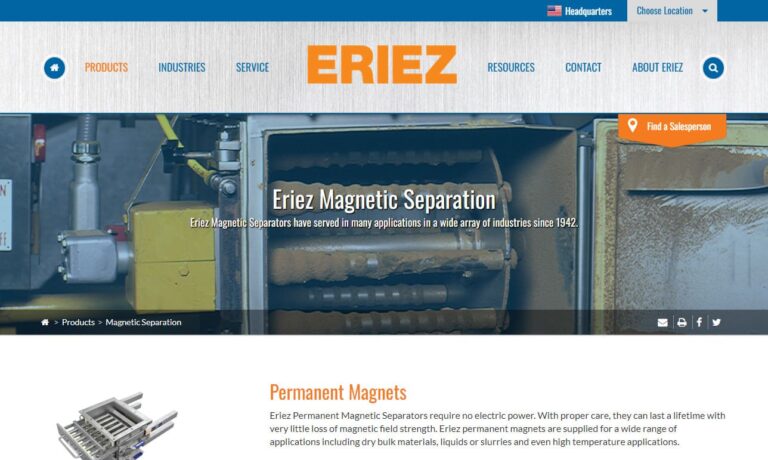

Since 1942, Eriez has been specializing in separation technology for a variety of industries. Eriez designs, develops, and manufactures magnets and related products. Eriez has 8 locations addition to their headquarters in Pennsylvania, making it convenient to ship their products all over the world. With proper care, Eriez magnet products can last a lifetime and not lose strength. Eriez offers...

At TyTek Industries, we are experts in manufacturing magnetic components. Our magnetics catalog include magnetic assembly, alnico magnets, rare earth magnets, and many more. It is our team’s mission to always draw on our strengths and experience to ensure the very best service and quality for our customers. For more information, visit our website or call today!

More Electromagnet Manufacturers

Scientific laboratories, manufacturing plants that handle scrap metal, the automotive industry and appliance and electronic manufacturers all benefit from the use of electromagnets. In addition, they are part of the design of electric motors, generators, doorbells, circuit breakers, TVs, speakers and read and write heads for hard disks and tape drives.

In the automotive industry, electromagnets are used to manufacture brakes and clutches in vehicles. In factories and plants, electromagnets are used to lift and suspend scrap metal and other heavy metallic objects like billets, steel plates, bars and forgings. In many of these applications a permanent magnet can be used instead of an electromagnet; however, electromagnets offer the advantage of being able to manipulate the magnetic field over a wide range at a rapid pace.

There are a few main components that are utilized in the formation of electromagnets: a battery and an iron wire. This wire is often formed into a coil, and can be formed into various shapes including that of a helix, making it a solenoid coil and that of a donut-shape, making it a toroid coil.

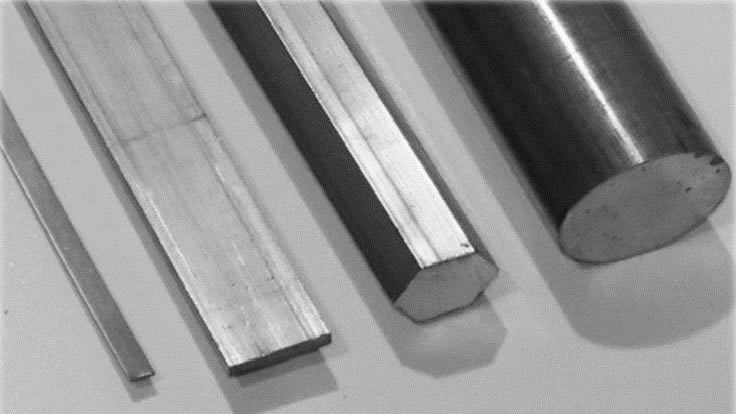

In addition, the material of iron is used as the wire component in electromagnets because it belongs to a small group of metals that exhibit ferromagnetic properties and generates a magnetic field when exposed to an electrical current. The magnetism only exists when current is flowing from the battery. This type of soft iron core is also referred to as a ferromagnetic core and offers extremely high magnetic permeability. There are two main types of electromagnets.

The first, flat-fraud, is mainly used when the magnet is able to attach itself to a smooth, flat piece of metal. Parallel-pole electromagnets have two poles spaced far apart from each other that allow the magnetic field to have a greater reach. These are used when the metallic object is of an irregular shape and only comes in partial contact with the magnet surface.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

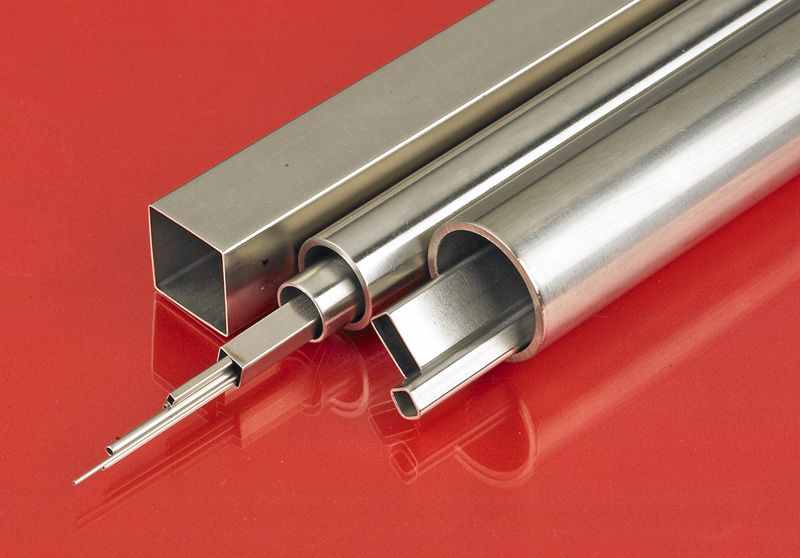

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

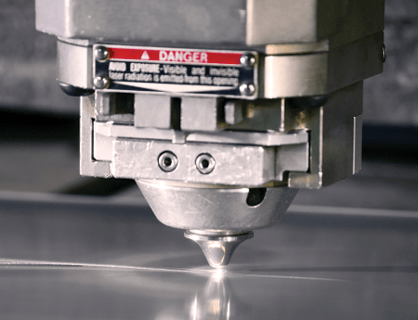

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

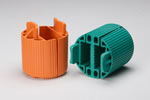

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services