In general, a wide spectrum of industries are increasingly using high-strength magnets to do all kinds of work, from physical metal lifting and separating to motor activation and Magnetic Resonance Imaging (MRI). Read More…

Founded in 1895, Arnold Magnetic Technologies is a leading global manufacturer of high performance permanent magnets, electromagnetics, magnetic assemblies, and precision thin metals.

Our customers know they can trust us to provide them with the best magnets in the industry. We supply magnets from only the best manufacturers in the world. We will not offer substandard products or anything that is not the most cost-effective solution.

CMS Magnetics excels as a leading magnet supplier, offering a vast array of high-quality neodymium, hard ferrite, SmCo, and AlNiCo magnets. We also provide diverse magnetic assemblies like pot magnets, channel magnets, and magnetic lifters, tailored for various applications. Our commitment to excellence is backed by a 100% customer satisfaction guarantee and a money-back promise. We accept custom ...

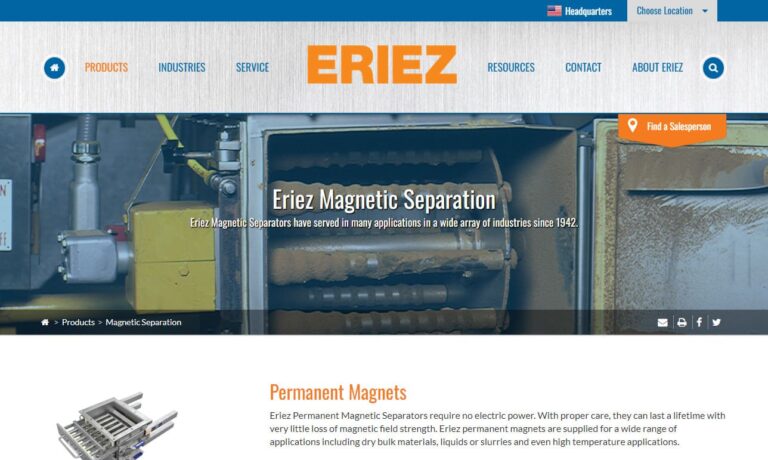

Since 1942, Eriez has been specializing in separation technology for a variety of industries. Eriez designs, develops, and manufactures magnets and related products. Eriez has 8 locations addition to their headquarters in Pennsylvania, making it convenient to ship their products all over the world. With proper care, Eriez magnet products can last a lifetime and not lose strength. Eriez offers...

At TyTek Industries, we are experts in manufacturing magnetic components. Our magnetics catalog include magnetic assembly, alnico magnets, rare earth magnets, and many more. It is our team’s mission to always draw on our strengths and experience to ensure the very best service and quality for our customers. For more information, visit our website or call today!

More Industrial Magnet Manufacturers

Different applications require different types of industrial magnets. Industrial magnets can be broken up into two main categories: non-permanent and permanent. Non-permanent magnets are electromagnets which require an outside electric current to be magnetized or demagnetized. Permanent magnets include ceramic magnets (also known as ferrite magnets), alnico magnets and rare earth magnets.

Ceramic magnets have lower magnetic power and are more brittle and easily breakable than some other magnets, but they are cost-effective and retain magnetism under corrosion and vibration. Rare earth magnets are less cost-effective to manufacture but are far more powerful and retain their magnetism better than ferrite magnets.

Neodymium magnets are the strongest and most commonly used industrial rare earth magnet; sheet magnets are made from a flexible ferrite-plastic composite which is extruded into sheets and used in automotive and consumer industries.

There are many different types of magnetic materials that industrial magnets can be fabricated from. The most important properties magnet manufacturers consider during fabrication are porosity; ease of fabrication; magnetic retention (or magnetic permanence) under heat, corrosion and vibration; magnetic strength; and cost.

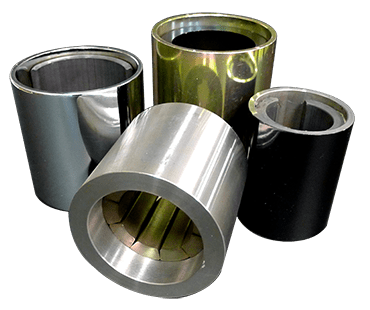

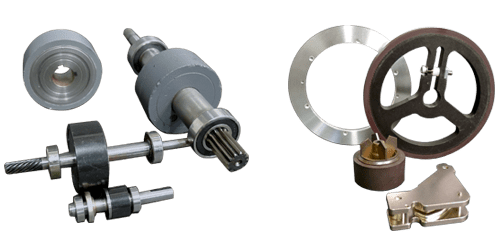

Types of permanent magnets are made from different composites and therefore have very different properties and applications. For instance, ceramic and alnico magnets are most often used for physical lifting and separating. Magnetic tools which do this kind of work often contain multiple magnets in specific configurations called magnetic assemblies.

Lifting, holding and separating magnetic assemblies are used in metal fabricating, construction, engineering, automotive, electronic, water treatment and agricultural industries among others. Arc-shaped ceramic magnets are often used in motors, and most stereo speakers use ceramic magnet discs.

Rare earth magnets and magnet assemblies have much stronger magnetic fields than ceramic or alnico magnets and are used in sensitive electric motor, computer hard drive, TV monitor, sensor and medical applications. Electromagnets are used by automotive, medical, metal fabrication and aerospace industries in applications such as solenoid valves, AC and DC motors, biomagnetic separation, beam control, transformers and car crushing.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

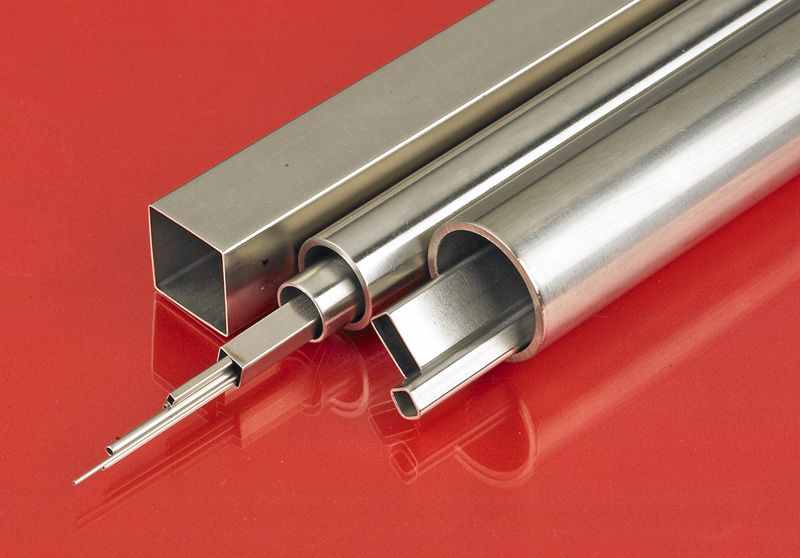

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

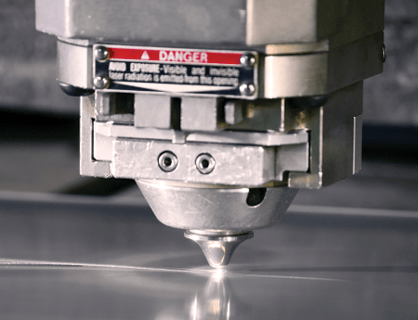

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services