Neodymium is a rare earth element that is known for its strong magnetic properties. Its ability to produce powerful magnetic fields makes it a highly sought-after material for creating magnets. In this article, we will discuss the process of creating neodymium magnets, considerations regarding their creation and use, and the various benefits and applications that they provide. Read More…

Founded in 1895, Arnold Magnetic Technologies is a leading global manufacturer of high performance permanent magnets, electromagnetics, magnetic assemblies, and precision thin metals.

Our customers know they can trust us to provide them with the best magnets in the industry. We supply magnets from only the best manufacturers in the world. We will not offer substandard products or anything that is not the most cost-effective solution.

CMS Magnetics excels as a leading magnet supplier, offering a vast array of high-quality neodymium, hard ferrite, SmCo, and AlNiCo magnets. We also provide diverse magnetic assemblies like pot magnets, channel magnets, and magnetic lifters, tailored for various applications. Our commitment to excellence is backed by a 100% customer satisfaction guarantee and a money-back promise. We accept custom ...

Since 1942, Eriez has been specializing in separation technology for a variety of industries. Eriez designs, develops, and manufactures magnets and related products. Eriez has 8 locations addition to their headquarters in Pennsylvania, making it convenient to ship their products all over the world. With proper care, Eriez magnet products can last a lifetime and not lose strength. Eriez offers...

At TyTek Industries, we are experts in manufacturing magnetic components. Our magnetics catalog include magnetic assembly, alnico magnets, rare earth magnets, and many more. It is our team’s mission to always draw on our strengths and experience to ensure the very best service and quality for our customers. For more information, visit our website or call today!

More Neodymium Magnet Manufacturers

The Process of Creating Neodymium Magnets

The process of creating neodymium magnets starts with the extraction of neodymium from the ground. Once extracted, it undergoes a series of purification steps to remove any impurities that may have been picked up during the extraction process. After purification, neodymium is alloyed with other metals such as iron and boron to create the neodymium magnet. The final step in the process involves magnetization, where the neodymium magnet is exposed to a strong magnetic field to align the magnetic domains within the material.

There are several processes used in creating neodymium magnets, such as the powder metallurgy process and the melt spinning process. The powder metallurgy process involves creating a fine powder of neodymium and alloying metals, which is then compressed and heated to form the magnet. The melt spinning process involves rapidly cooling a molten alloy of neodymium and other metals to create a ribbon, which is then ground into a fine powder and compressed to form the magnet.

The choice of process depends on the intended application of the magnet. For example, the powder metallurgy process is more suitable for creating magnets with complex shapes, while the melt spinning process is more suitable for creating magnets with high magnetic performance.

Considerations Regarding Neodymium Magnets

The creation and use of neodymium magnets come with some considerations to take into account. To begin with, the mining of neodymium can have significant environmental impacts, such as soil erosion and contamination of groundwater. Additionally, neodymium magnets can be hazardous to human health if ingested or inhaled, as they may cause harm to internal organs. Finally, neodymium magnets can also be dangerous to electronic devices, such as pacemakers and credit cards.

Benefits Provided by Neodymium Magnets

Despite the negative considerations, neodymium magnets provide several benefits that make them highly desirable. Let’s examine these benefits in greater detail.

High Magnetic Performance

Neodymium magnets are known for their high magnetic performance, which refers to their ability to generate a strong magnetic field with a relatively small size. This makes them ideal for applications where space is limited or where high magnetic strength is required.

High Energy Density

Neodymium magnets have a high energy density, which means that they can store a large amount of energy in a small space. This makes them ideal for creating compact and efficient machines, such as electric motors and generators.

Corrosion Resistance

Neodymium magnets have good corrosion resistance, which means that they are less likely to corrode or rust over time. This makes them ideal for applications in harsh environments, such as marine and aerospace applications.

Temperature Stability

Neodymium magnets have good temperature stability, which means that they can maintain their magnetic properties over a wide temperature range. This makes them ideal for applications where high temperatures or temperature changes are expected, such as in electric motors and generators.

Versatility

Neodymium magnets are highly versatile and can be used in a wide range of applications, from consumer electronics to medical devices to aerospace applications. This versatility is due to their high magnetic strength and compact size, which makes them suitable for a variety of applications.

Applications of Neodymium Magnets

As a result of these benefits, neodymium magnets find application in several industries, including:

Electric Motors and Generators

Neodymium magnets are used in electric motors and generators, where their strong magnetic force and high performance make them an excellent choice for creating efficient and powerful machines.

Hard Disk Drives

Neodymium magnets are used in hard disk drives to read and write data. Their high magnetic performance makes them an ideal choice for creating high-density storage media.

Magnetic Resonance Imaging Machines (MRI)

Neodymium magnets are used in MRI machines to create strong magnetic fields that are used to image internal organs and tissues.

Magnetic Separation

Neodymium magnets are used in the separation of magnetic materials from non-magnetic materials in industries such as recycling and mining.

Loudspeakers and Headphones

Neodymium magnets are used in loudspeakers and headphones to create clear and high-quality sound.

Magnetic Toys

Neodymium magnets are used in magnetic toys such as building blocks and puzzles.

Jewelry Clasps

Neodymium magnets are used in jewelry clasps to create a secure and easy-to-use closure.

Wind Turbines

Neodymium magnets are used in wind turbines to help generate electricity. They are placed in the generator to create a magnetic field that interacts with the coils of wire to produce an electrical current.

Marine and Aerospace Applications

Neodymium magnets are often used in marine and aerospace applications because of their high magnetic strength and resistance to corrosion. In marine applications, they can be found in underwater motors, sensors, and magnetic couplings. In aerospace applications, they are used in electric generators, actuators, and sensors.

Consumer Electronics

Neodymium magnets are widely used in consumer electronics, such as smartphones, headphones, and laptops. They are used in speakers, microphones, and vibration motors due to their compact size and high magnetic strength.

Medical Devices

Neodymium magnets are also used in medical devices due to their high magnetic strength and biocompatibility. As a result, they are used in implantable devices, such as pacemakers, to maintain the positioning of the device.

Choosing the Correct Neodymium Magnet Supplier

To ensure you have the most constructive outcome when purchasing neodymium magnets from a neodymium magnet supplier, it is important to compare several companies using our directory of neodymium magnet suppliers. Each neodymium magnet supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each neodymium magnet business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple neodymium magnet companies with the same form.

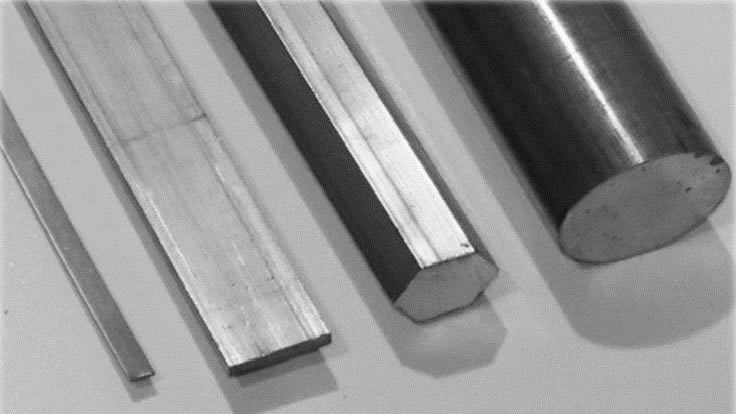

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

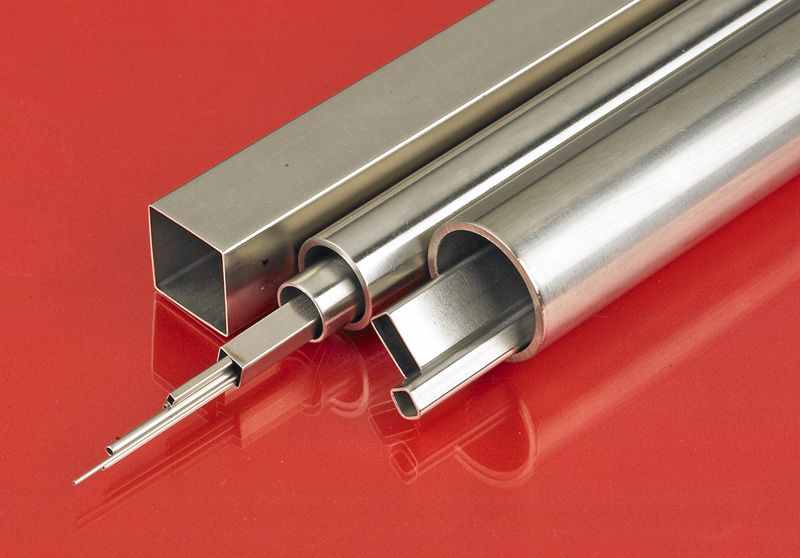

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

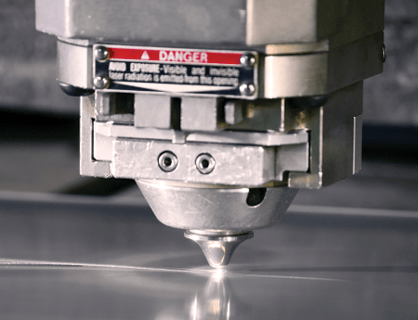

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services