A magnet is defined as an object or piece of material that generates a magnetic field. The magnetic field is moving electrical charges that cause other magnetic objects to either be attracted to or repelled from the magnet. A tool or system that utilizes magnets or magnet combinations to perform a specific type of function is known as a magnetic assembly. Read More…

Founded in 1895, Arnold Magnetic Technologies is a leading global manufacturer of high performance permanent magnets, electromagnetics, magnetic assemblies, and precision thin metals.

Our customers know they can trust us to provide them with the best magnets in the industry. We supply magnets from only the best manufacturers in the world. We will not offer substandard products or anything that is not the most cost-effective solution.

CMS Magnetics excels as a leading magnet supplier, offering a vast array of high-quality neodymium, hard ferrite, SmCo, and AlNiCo magnets. We also provide diverse magnetic assemblies like pot magnets, channel magnets, and magnetic lifters, tailored for various applications. Our commitment to excellence is backed by a 100% customer satisfaction guarantee and a money-back promise. We accept custom ...

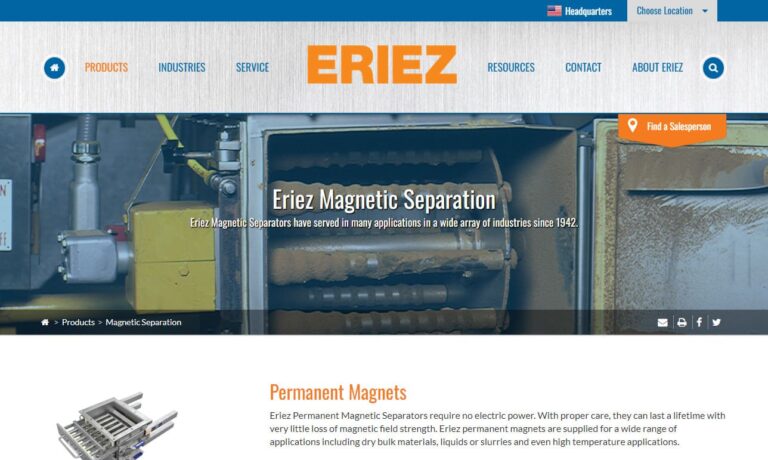

Since 1942, Eriez has been specializing in separation technology for a variety of industries. Eriez designs, develops, and manufactures magnets and related products. Eriez has 8 locations addition to their headquarters in Pennsylvania, making it convenient to ship their products all over the world. With proper care, Eriez magnet products can last a lifetime and not lose strength. Eriez offers...

At TyTek Industries, we are experts in manufacturing magnetic components. Our magnetics catalog include magnetic assembly, alnico magnets, rare earth magnets, and many more. It is our team’s mission to always draw on our strengths and experience to ensure the very best service and quality for our customers. For more information, visit our website or call today!

More Magnet Assembly Manufacturers

Applications of Magnets

Magnetic assemblies serve specialized purposes such as holding, lifting, or separating magnetic materials. By combining different magnet types in these assemblies, their magnetic force can be amplified.

Industrially and in manufacturing, magnetic assemblies find diverse applications. They facilitate mounting, holding, water treatment, and lifting of sheet metals and metal parts. Additionally, they are employed in lighter tasks like holding papers, exemplified by fridge magnets.

Various systems and products rely heavily on magnetic assemblies. These encompass a wide array of applications such as activating electric motors, utilizing eddy currents, conducting blood tests and separations, driving linear actuators, controlling ignition timing, measuring power consumption, operating welding equipment, displaying TV monitors, sensing environments, reproducing sound through speakers, conducting MRIs, powering automotive and electronic devices, supporting biomedical and aerospace technologies, programming and erasing film and software disks.

The History of Magnet Assemblies

Modern magnet assemblies trace their origins to lodestones, naturally magnetized pieces of iron ore used by ancient civilizations as compasses. The earliest lodestone compasses were employed by ancient Greeks, Chinese mariners, and people in ancient India. The term “magnet” entered the English language during the late Middle English period, borrowed from the Latin word “magnetum”. By the 12th and 13th centuries, mariners worldwide relied on magnetic compasses, though they lacked an understanding of how magnetism operated.

The systematic study of magnetism began with William Gilbert in 1600. Gilbert explored the effects of temperature on magnetism and developed techniques for magnet manufacturing. He also concluded that the Earth itself behaves like a giant magnet, documenting his findings in his seminal work “De Magnete, Magneticisque Corporibus, et de Magno Magnete Tellure” (On the Magnet and Magnetic Bodies, and on the Great Magnet the Earth).

In 1819, Danish scientist and professor Hans Christian Ørsted stumbled upon a groundbreaking revelation: placing a magnet near an electrical current induces a magnetic field. This accidental discovery spurred numerous scientific investigations into magnetism and electromagnetism. Throughout the 1800s, driven by these findings, scientists and engineers developed rudimentary magnet-powered devices and basic electromagnetic generators.

In the 20th century, groundbreaking discoveries by scientists like J.J. Thomson and James Clerk Maxwell paved the way for engineers to revolutionize magnetic technologies. The theoretical groundwork for superconductor magnets began as early as 1911, but it wasn’t until 1954 that practical applications emerged. The late 20th century witnessed a significant breakthrough with the introduction of rare-earth magnets, renowned for their immense industrial strength. In 1982, a collaborative effort between General Motors and Sumitomo Special Metals led to the development of the neodymium magnet, offering a more cost-effective alternative to the samarium–cobalt magnet.

Since rare earth magnets were discovered and developed, manufacturers have significantly enhanced their ability to create stronger and more varied magnetic assemblies. In 2010 alone, over 129,000 metric tons of rare earth metals were harvested. Today, custom magnet assemblies play a crucial role in powering a wide array of technologies, including machines, electronics, vehicles, aircraft, medical devices, and beyond.

Magnet Assembly Design

Various types of permanent magnets derive from a diverse array of materials, each possessing distinct characteristics. Common materials used in magnet production include sintered ceramic powder composites (consisting of iron oxide, ceramic powder, and either barium or strontium), alnico alloys (primarily aluminum, nickel, and cobalt), and rare earth elements such as neodymium iron boron (NdFeB) and samarium cobalt (SmCo).

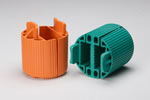

Manufacturers employ various processes to create magnet assemblies. For instance, ceramic magnets can be extruded, compressed, or sintered into a wide range of shapes.

Magnet manufacturers consider various properties when making magnets, such as porosity, ease of fabrication, magnetic retention in high temperatures and corrosive environments, magnetic strength, and cost. They also offer custom magnet assemblies tailored to specific needs. For more information on custom magnets, consult your supplier.

Types of Magnets

Magnets exist in diverse types, each differing in magnetic strength, heat resistance, permanence, and tolerance to corrosion.

Magnets fall into two primary categories: permanent and non-permanent. Within these groups, they further branch into types like electromagnets and superconductors. Additionally, magnets vary by composition, such as ceramic, alnico, rare earth (like samarium cobalt and neodymium), each suited for distinct applications. Furthermore, magnets are defined by their shape or purpose, tailored for specific industries or uses, ranging from sheet and bar magnets to strips and specialized bipolar assemblies.

Permanent magnets retain their magnetism autonomously, without reliance on external forces, and they neither produce heat nor generate electricity. They represent the predominant form of magnet in everyday use.

Non-permanent magnets, activated by external power sources like robust magnetic fields, are commonly crafted from ferrous materials for applications in electronics.

Electromagnets, or electro magnets, rely on an external power source to generate magnetism. This source is typically the magnetic field created by electric currents flowing through tightly wound wire coils. Their magnetic force can be controlled, allowing them to be activated or deactivated as needed. Electromagnets find extensive use across industries such as in solenoid valves, biomagnetic separation, AC and DC motors, and electric transformers.

Superconductors, unlike conventional magnets with metal cores, achieve unparalleled magnetic strength. They require cooling to extremely low temperatures. Their applications are predominantly in heavy-duty machinery like MRI and magnetic separator machines.

Ceramic magnets, also called ferrite magnets, belong to the category of permanent magnets. They exhibit relatively low magnetic strength and are brittle, making them susceptible to breakage compared to other magnet types. However, their cost-effectiveness makes them widely used in applications such as magnetic tools, chucks, and motors.

Alnico magnets, as permanent magnets, are slightly pricier than ceramic magnets. They share similarities with ceramic magnets but offer advantages such as greater durability, higher magnetic strength, and easier shaping capabilities.

Rare earth magnets incur higher manufacturing costs compared to ceramic magnets, yet their superior strength and magnetism retention make them worth the investment. This increased cost stems from the scarcity of rare earth materials and the complex extraction process involved in obtaining them from lanthanide ores, distinguishing them as pricier alternatives to non-rare-earth magnets.

They serve as crucial industrial magnets, finding applications in diverse fields such as MRIs, testing equipment, sensors, speakers, motors, and for tasks involving holding and lifting.

Two primary types of rare earth magnets are samarium cobalt and neodymium magnets. Both derive their magnetic strength from samarium and neodymium, elements characterized by partially filled outer f-electron shells, which contribute significantly to their powerful magnetic fields.

Samarium cobalt magnets consist of a blend of samarium and cobalt, prized for their exceptional resistance to corrosion and demagnetization. They are notably heat-resistant, maintaining stability even at temperatures as high as 550℃. This thermal durability makes samarium cobalt magnets essential in demanding applications such as medical tools and motors that operate under extreme heat conditions.

Neodymium magnets stand out for their exceptional magnetic strength, surpassing all other magnet types. In addition to their superior hardness compared to ceramic magnets, they exhibit heightened susceptibility to heat and corrosion. These magnets are crafted from a blend of boron, iron, and neodymium, with a nickel coating applied to mitigate their inherent brittleness.

Sheet magnets are crafted from a blend of ferrite and plastic, forming a composite material. Manufacturers process this composite by extruding it into sheets with magnetic properties, which are then cut into flexible rubber strips. These magnets find widespread application in automotive and consumer industries alike.

Bar magnets stand out as the most prevalent form of magnets. Crafted from ferrite metals, these magnets typically take the shape of a slender rectangle or bar.

Strip assemblies consist of slender rubber magnet segments coated with adhesive, ideal for adhering to irregular surfaces.

Bipolar assemblies are resilient structures designed for items needing strong alignment or secure fastening, especially in high-temperature environments.

Advantages of Magnet Assemblies

Magnet assemblies serve as vital components across various technologies, providing numerous benefits beyond their primary functions. Firstly, they facilitate efficient sorting and separation of metal materials, swiftly distinguishing ferrous metals such as stainless steel and carbon steel from non-ferrous ones like copper and aluminum. Secondly, they contribute to cost-effective maintenance and prolonged product lifespan by averting damage and minimizing wear and tear. For instance, they effectively prevent tire punctures. Lastly, they safeguard against contamination by attracting and retaining magnetic and ferrous materials during storage and on production lines.

Magnet Assembly Accessories

Typical magnetic assembly accessories comprise adhesives, connectors, protective covers, and ferrous components.

Uses for Magnet Assemblies

When using or handling your magnet assemblies, strict adherence to safety protocols is crucial for you and your staff.

First, ensure you wear both gloves and goggles. Gloves are essential to protect your skin from cuts and abrasions that could result from mishandling magnets or if they shatter. Goggles shield your eyes from magnet shards and sparks during machining. Second, never enter the assembly area if you have a pacemaker. Magnetic assemblies can interfere with electronic devices, potentially causing harm or even fatal consequences for pacemaker users. Similarly, keep all electronics away from magnets to prevent interference. Additionally, when transporting magnets, beware of interference with navigation systems or attraction to magnetic surfaces. Use an isolating container to mitigate these risks. Lastly, if you’re allergic to metal dust, take precautions against inhalation by wearing a protective mask. If you or your team members have contact allergies, use protective clothing or avoid the area as necessary.

Types of Magnets Used in Speakers

Magnets play crucial roles in loudspeakers, speakers, and headphones, each contributing distinct tone qualities. Speaker magnets vary in strength, ranging from 0.001 to 1.5 teslas, depending on their size and type. Compared to those in loudspeakers, headphone magnets are generally less powerful. To achieve desired sound output while minimizing speaker size, stronger magnets are essential. Here’s a breakdown of the types of magnets commonly used in speakers:

Neodymium magnets, renowned as the most potent among rare earth magnets, enhance speaker performance with impressive sound quality. Their magnet strength can reach up to 1.5 teslas, making them ideal for medium and high-grade headphones. Neodymium magnets excel in miniaturizing speakers, enabling compact designs that maintain strong magnetic fields within small enclosures. Specifically, they are perfect for tweeter drivers, specializing in delivering high frequencies, with even the smallest magnets boasting strengths starting at 0.001 teslas.

Neodymium magnets in speakers offer superior tone quality, enhanced sound elasticity, and precise frequency response. Their robustness contributes significantly to their accurate frequency handling. Widely recognized for delivering unmatched performance, neodymium magnets excel in power. Yet, their susceptibility to brittleness means they can crack under high impacts.

Ceramic or ferrite magnets are larger in size, making them ideal for use in large drivers found in mid-range to high-range woofers and subwoofers. Their size allows them to excel at producing clear sound even at high speaker volumes, albeit at the cost of increased weight for the speakers using them. Moreover, their corrosion resistance makes them well-suited for marine sounder applications and other damp environments. Unlike neodymium magnets, ceramic magnets can maintain their magnetic strength over extended periods without the need for a stronger magnetic field nearby. Additionally, their lower cost enables mass production, making them a preferred choice when durability and affordability are key factors to consider.

Alnico magnets, composed of aluminum, iron, nickel, and cobalt alloys, were pioneers in early permanent magnet drivers. They impart a classic, warm tone to speakers. Renowned for their durability, alnico magnets resist cracking and exhibit superior thermal and corrosion resistance compared to neodymium magnets. This resilience makes them favored in external applications like horns. Their standout feature lies in easy magnetization and precise weakening, enabling precise tuning for optimal acoustic performance.

Larger magnets are essential for bigger speakers, yet sound quality hinges on more than just size. Factors like speaker-level audio signals, heat resistance of voice coils, optimal speaker enclosures, and more play crucial roles. The choice of magnet size depends largely on the intended use. For large speaker cones and subwoofers, larger magnets are necessary to drive cone vibrations effectively. Conversely, tweeters require smaller magnets to facilitate rapid production of high frequencies. Assuming equal magnetic strength, larger magnets yield louder sounds, while smaller magnets produce weaker ones. High-end speakers often employ multiple driver sizes to cater to varying frequency responses: larger speakers excel in low-frequency sound reproduction, whereas smaller ones are adept at high frequencies.

Proper Care for Magnet Assemblies

To ensure your magnets maintain longevity and optimal functionality, it’s essential to follow a few maintenance practices. Firstly, if your magnets bear loads, regular testing is advised to ensure they maintain their load-bearing capacity. Secondly, periodic cleaning and decontamination are crucial. Since each magnet type varies, consulting your supplier for specific cleaning methods and materials tailored to your assembly is highly recommended.

Finding the Right Magnet Manufacturer

Looking for a magnetic assembly? It’s crucial to team up with a reliable custom magnet manufacturer who truly understands your requirements. Check out the industry leaders we’ve featured on this page—they boast stellar track records. As you explore, consider factors like volume needs, specific magnet requirements, budget constraints, timeline expectations, and delivery preferences. Narrow down your choices to three or four suppliers that align best with your criteria. Engage each one extensively about your application. Afterward, compare and contrast your discussions to pinpoint the ideal manufacturer for your needs and begin collaborating.

Check out our Linear Actuators website

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

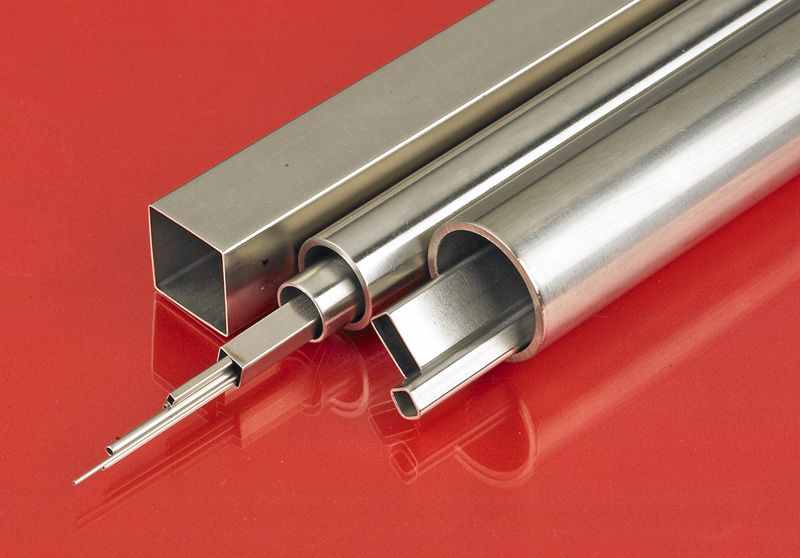

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

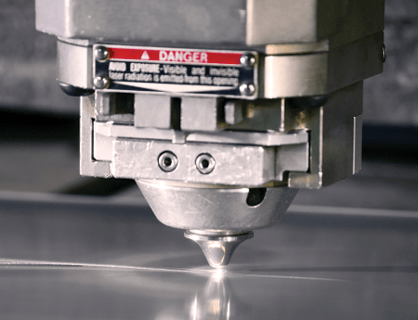

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services