Rare earth magnets are a type of permanent magnet that has become essential in many industries due to their exceptional magnetic strength and energy efficiency. They are widely used in consumer electronics, medical devices, renewable energy, aerospace and defense, and industrial automation equipment, among others. In this article, we will delve deeper into the origin and production of rare earth magnets, their different types and applications, as well as the considerations regarding their production, and benefits associated with them. Read More…

Founded in 1895, Arnold Magnetic Technologies is a leading global manufacturer of high performance permanent magnets, electromagnetics, magnetic assemblies, and precision thin metals.

Our customers know they can trust us to provide them with the best magnets in the industry. We supply magnets from only the best manufacturers in the world. We will not offer substandard products or anything that is not the most cost-effective solution.

As a premium magnet vendor, CMS Magnetics offers magnetic assemblies including large magnetics, strong magnets and super strong magnets for various applications. Confident in CMS Magnetics magnet quality over the quality of other magnet companies, CMS Magnetics offers 100% customer satisfaction and a money back guarantee. CMS Magnetics takes custom orders for magnets in all magnetic materials.

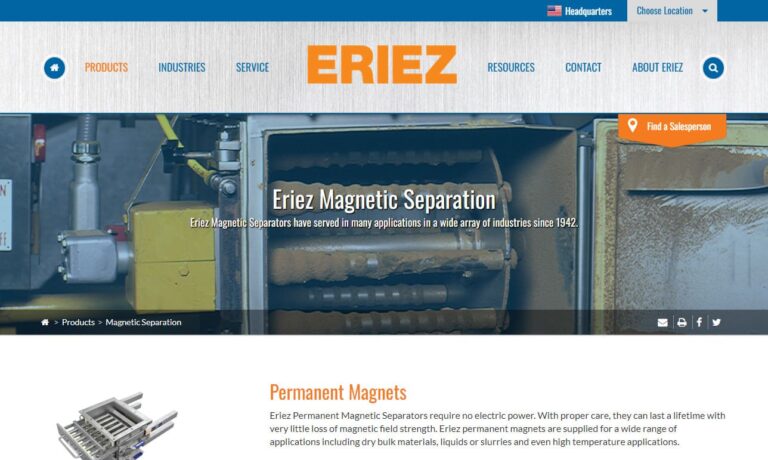

Since 1942, Eriez has been specializing in separation technology for a variety of industries. Eriez designs, develops, and manufactures magnets and related products. Eriez has 8 locations addition to their headquarters in Pennsylvania, making it convenient to ship their products all over the world. With proper care, Eriez magnet products can last a lifetime and not lose strength. Eriez offers...

At TyTek Industries, we are experts in manufacturing magnetic components. Our magnetics catalog include magnetic assembly, alnico magnets, rare earth magnets, and many more. It is our team’s mission to always draw on our strengths and experience to ensure the very best service and quality for our customers. For more information, visit our website or call today!

At US Magnetix, we offer a wide-variety of industrial magnets including ceramic magnets, magnet receptive, magnet rolls, magnet sheets, magnet tape, neodymium magnets, and many more. We believe that our magnets are only as great as the materials used to make it. That’s why our high-quality industrial magnets are the best fit for any type of project and any size production run. Contact US...

More Rare Earth Magnet Manufacturers

Origin and Production of Rare Earth Magnets

Rare earth magnets are primarily made from two types of rare earth metals: neodymium and samarium. These metals are found in abundance in several countries worldwide, including China, the United States, Australia, and Brazil. China, however, is the largest producer and supplier of rare earth metals, accounting for over 70% of the world's production. The production process of rare earth magnets involves extracting the metals from their ores, refining them, and then transforming them into magnet alloy through a process known as sintering. Sintering is a process of compacting and forming a solid mass by heating a powdered material without melting it. The sintered material is then magnetized, and the magnets are formed into their desired shapes.

Types of Rare Earth Magnets and Their Specific Applications

The two most commonly used types of rare earth magnets are neodymium magnets and samarium cobalt magnets. Neodymium magnets are the strongest type of rare earth magnets and have a wide range of applications, such as in electric motors, headphones, wind turbines, and MRI machines. Samarium cobalt magnets, on the other hand, have high resistance to heat and corrosion, making them suitable for use in aerospace and defense applications, such as in missile guidance systems, satellites, and electric motors for aircraft.

Other types of rare earth magnets include dysprosium, terbium, and gadolinium magnets. These types of magnets are used in specific applications, such as in nuclear magnetic resonance imaging, magneto-optical devices, and in electronic devices that require high-temperature stability.

Considerations Regarding Rare Earth Magnets

The production of rare earth magnets is associated with environmental and health impacts. The mining of rare earth metals often leads to soil and water pollution, as well as habitat destruction, which can result in the loss of biodiversity. The production process also releases harmful gasses and particles, such as sulfur dioxide and particulate matter, which can cause respiratory problems and other health issues.

Benefits Provided by Rare Earth Magnets

Despite these considerations associated with rare earth magnets, they provide significant benefits to various industries. Rare earth magnets have a high magnetic strength, which enables them to produce strong magnetic fields with minimal input power. They are also resistant to demagnetization and can maintain their magnetic strength over long periods. Additionally, rare earth magnets are small and lightweight, making them ideal for use in portable electronic devices. They are also energy-efficient, as they can convert electrical energy into mechanical energy with high efficiency.

Applications of Rare Earth Magnets

As a result of these beneficial properties, rare earth magnets have a wide range of applications across various industries, including:

Consumer Electronics

In consumer electronics, they are used in smartphones, computers, headphones, and other audio devices.

Medical Devices

Medical devices, such as MRI machines and pacemakers, also rely on rare earth magnets.

Renewable Energy

Renewable energy sources, such as wind turbines and electric vehicles, use rare earth magnets to generate electricity and power electric motors.

Aerospace and Defense

In aerospace and defense, rare earth magnets are used in missile guidance systems, satellites, and other applications that require high strength and resistance to heat and corrosion.

Industrial Automation and Robotics

Industrial automation and robotics also use rare earth magnets in various applications.

Electric Motors and Generators

Rare earth magnets are widely used in electric motors and generators because they provide high magnetic fields in a small size, making them more efficient and compact.

Hard Disk Drives

Rare earth magnets are used in the voice coil motor of hard disk drives, which helps position the read/write head to access the data stored on the disk.

Magnetic Levitation (Maglev) Trains

Rare earth magnets are used in the propulsion system of Maglev trains, which use magnetic fields to levitate and propel the train along the track.

Choosing the Right Rare Earth Magnet Supplier

To ensure you have the most positive outcome when purchasing rare earth magnets from a rare earth magnet supplier, it is important to compare several companies using our directory of rare earth magnet suppliers. Each rare earth magnet supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each rare earth magnet business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple rare earth magnet companies with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services