TMC Magnetics, Inc.

TMC Magnetics, Inc. Request A Quote

Wayne, NJTMC Magnetics, Inc. is a leading provider of magnet assemblies and related services, catering to a wide range of industries and applications. With a strong focus on innovation, quality, and customer satisfaction, TMC Magnetics has established itself as a trusted partner in the field of magnetic solutions. Product Offering: Magnet Assemblies TMC Magnetics specializes in the design, development, and manufacturing of magnet assemblies. These magnet assemblies consist of permanent magnets, such as neodymium, samarium cobalt, and ceramic magnets, combined with various metal or non-metal components to create functional magnetic systems. TMC Magnetics offers a diverse range of magnet assemblies, including but not limited to: 1. Magnetic Sensors: TMC Magnetics produces magnet assemblies that are used in magnetic sensors, providing accurate detection and measurement of magnetic fields. These sensors find applications in automotive, industrial automation, medical devices, and consumer electronics. 2. Magnetic Separators: The company's magnet assemblies are designed for magnetic separation applications, effectively removing ferrous contaminants from various materials, such as food products, pharmaceuticals, chemicals, and minerals. TMC Magnetics' magnetic separators ensure enhanced product purity and prevent equipment damage. 3. Magnetic Couplings: TMC Magnetics offers magnet assemblies for magnetic couplings used in pumps, mixers, and other rotating equipment. These couplings transmit torque without physical contact, enabling a hermetic seal between the driving and driven components. Magnetic couplings are widely used in industries where leakage prevention is critical, such as chemical processing and water treatment. 4. Magnetic Lifters: TMC Magnetics manufactures magnet assemblies for magnetic lifters, which provide a safe and efficient solution for lifting and transporting heavy objects. These lifters find applications in construction, manufacturing, warehouses, and logistics, offering significant time and labor savings. Service Capabilities: In addition to its comprehensive product offering, TMC Magnetics provides a range of services to meet the unique requirements of its customers. These service capabilities include: 1. Customization: TMC Magnetics collaborates closely with its clients to understand their specific needs and offers customized magnet assemblies tailored to their application requirements. The company's team of experienced engineers and technicians work closely with customers to design, prototype, and manufacture magnet assemblies that meet the highest quality standards. 2. Engineering Support: TMC Magnetics provides engineering support throughout the entire project lifecycle. From feasibility studies and concept development to design optimization and validation, the company's team ensures that magnet assemblies are engineered for optimal performance, reliability, and cost-effectiveness. 3. Testing and Quality Assurance: TMC Magnetics maintains rigorous quality control processes to ensure that its magnet assemblies meet the highest standards. The company conducts comprehensive testing and inspections at various stages of production to guarantee the performance, durability, and consistency of its products. 4. After-Sales Support: TMC Magnetics is committed to providing exceptional customer service even after the sale. The company offers technical assistance, troubleshooting, and product maintenance support to ensure the long-term satisfaction and success of its customers. Conclusion: TMC Magnetics, Inc. stands at the forefront of the magnet assembly industry, offering innovative solutions and reliable services to a diverse range of sectors. With a strong emphasis on quality, customization, and customer-centricity, TMC Magnetics continues to be a preferred choice for businesses seeking high-performance magnet assemblies and comprehensive support throughout their projects.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

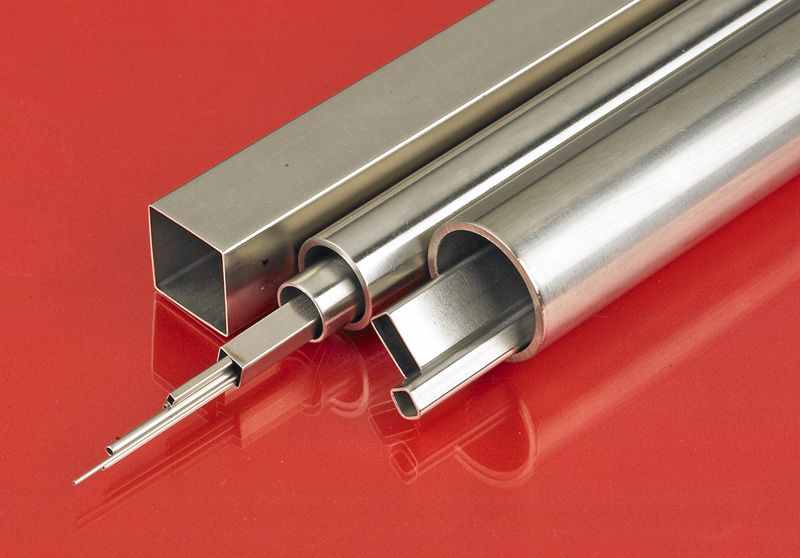

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

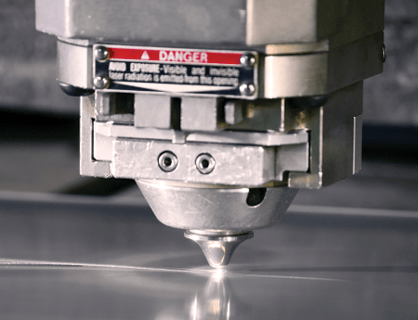

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

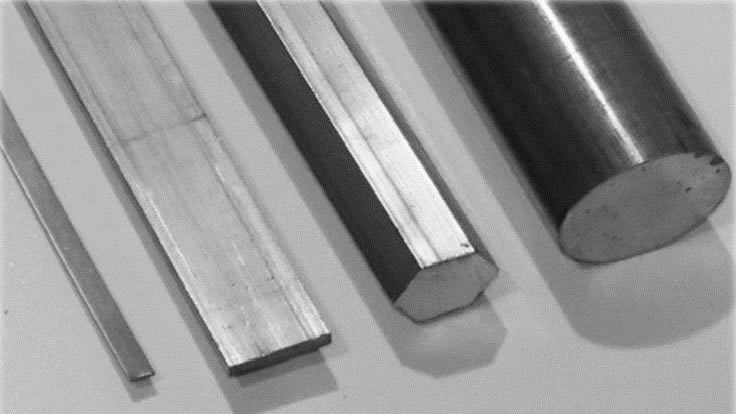

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

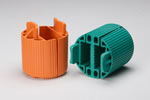

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services