Polaris Rare Earth Materials, LLC

Polaris Rare Earth Materials, LLC Request A Quote

Carmel, INPolaris Rare Earth Materials, LLC is a leading provider of high-quality magnet assemblies and related services. With a strong focus on rare earth materials, we are committed to delivering innovative solutions to meet the growing demand for advanced magnet technologies in various industries. At Polaris Rare Earth Materials, we understand the critical role that magnets play in a wide range of applications, from renewable energy and transportation to aerospace and medical devices. Leveraging our expertise in rare earth materials, we design, manufacture, and supply magnet assemblies that are tailored to meet the unique requirements of our customers. Our Magnet Assemblies division is dedicated to producing cutting-edge magnet solutions that deliver exceptional performance, reliability, and efficiency. We have a state-of-the-art manufacturing facility equipped with advanced equipment and technologies, allowing us to produce magnet assemblies of various sizes, shapes, and specifications. Key Features of our Magnet Assemblies: 1. Customized Design: We work closely with our customers to understand their specific needs and application requirements. Our team of experienced engineers uses advanced design software and simulation tools to develop tailor-made magnet assemblies that optimize performance and functionality. 2. High-Quality Materials: As our name suggests, we specialize in rare earth materials, including neodymium, samarium cobalt, and other magnet alloys. These materials offer superior magnetic properties, enabling us to create magnet assemblies with exceptional strength and stability. 3. Precision Manufacturing: Our manufacturing processes follow stringent quality control standards to ensure consistent and reliable magnet assemblies. We employ advanced machining, molding, and assembly techniques to achieve precise tolerances and eliminate defects. 4. Versatile Applications: Our magnet assemblies find applications in various industries, including automotive, renewable energy, robotics, electronics, and more. Whether it's for electric motors, magnetic sensors, magnetic separators, or magnetic levitation systems, we have the capabilities to meet diverse industry demands. Service Capabilities: In addition to our magnet assembly products, we offer a comprehensive range of services to support our customers throughout the entire project lifecycle: 1. Engineering Support: Our team of skilled engineers provides expert guidance and assistance during the design and development phase. We collaborate with customers to optimize magnet assembly performance, improve efficiency, and reduce costs. 2. Prototyping and Testing: We offer rapid prototyping services, allowing customers to validate their designs and assess magnet assembly performance before full-scale production. Our testing facilities enable comprehensive evaluation of mechanical, thermal, and magnetic properties. 3. Customization and Modification: We understand that each customer's requirements may be unique. Therefore, we offer customization and modification services to adapt our magnet assemblies to specific applications, ensuring seamless integration and optimal performance. 4. Supply Chain Management: As a reliable partner, we ensure a streamlined supply chain to meet customer demands promptly. We maintain strategic relationships with trusted rare earth material suppliers, enabling us to source the highest quality materials and deliver on time. 5. Technical Support and Maintenance: Our commitment to customer satisfaction goes beyond product delivery. We provide ongoing technical support, troubleshooting assistance, and maintenance services to ensure the long-term performance and durability of our magnet assemblies. Polaris Rare Earth Materials, LLC is dedicated to driving innovation, quality, and customer satisfaction in the field of magnet assemblies. With our expertise in rare earth materials and commitment to excellence, we strive to be the preferred partner for organizations seeking advanced magnet solutions for their critical applications.

Alloy Suppliers

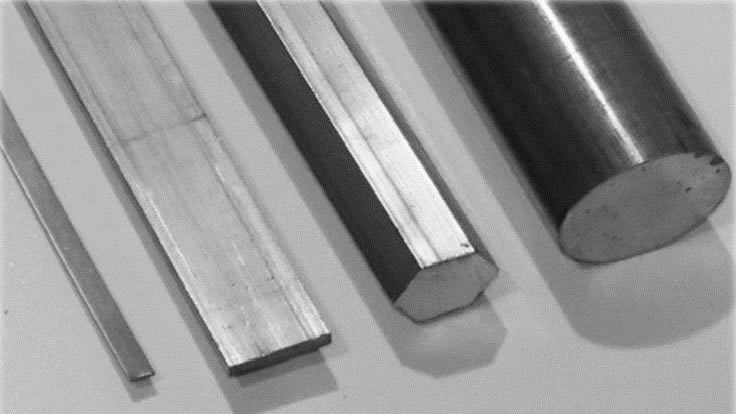

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

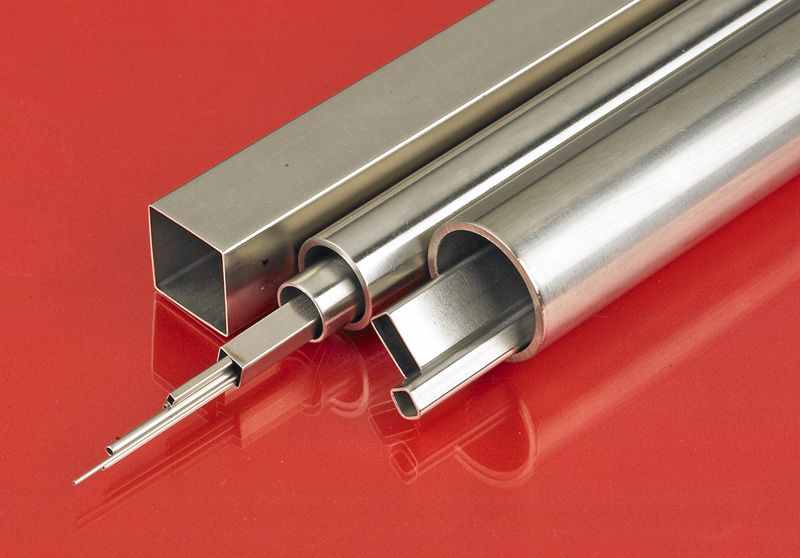

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

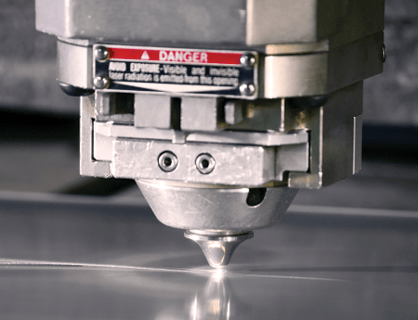

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services