Magni-Power Company Magnetics Division

Magni-Power Company Magnetics Division Request A Quote

Wooster, OHMagni-Power Company Magnetics Division is a leading provider of high-quality Magnet Assemblies products and services. With a strong commitment to innovation, reliability, and customer satisfaction, our company has established itself as a trusted name in the industry. Product Offerings: At Magni-Power Company Magnetics Division, we specialize in designing and manufacturing a wide range of Magnet Assemblies tailored to meet the diverse needs of our customers. Our extensive product line includes permanent magnets, magnetic assemblies, magnetic cores, and custom magnetic solutions. We offer magnets in various shapes, sizes, and magnetic materials, including neodymium (NdFeB), samarium cobalt (SmCo), ceramic, and alnico. Service Capabilities: We take pride in our ability to provide comprehensive services to our customers. Our experienced team of engineers and technicians work closely with clients to understand their specific requirements and develop customized solutions that meet their unique needs. With our state-of-the-art facilities and advanced manufacturing technologies, we have the capabilities to handle projects of any size or complexity. Design and Engineering: Our dedicated design and engineering team has the expertise to create magnet assemblies that optimize performance, durability, and efficiency. Using advanced CAD and simulation software, we can simulate and analyze magnetic fields, ensuring the optimal design for each application. Our engineers work closely with customers to translate their ideas and specifications into viable products, ensuring the highest level of quality and functionality. Prototyping and Testing: We understand the importance of validating designs before full-scale production. That's why we offer prototyping services to help customers evaluate the performance and feasibility of their magnet assemblies. Our well-equipped prototyping facilities allow for quick turnaround times, enabling efficient design iterations and refinement. Through rigorous testing, we ensure that our products meet or exceed industry standards for reliability, performance, and safety. Manufacturing and Production: With our modern manufacturing facilities and advanced production techniques, we have the capacity to handle high-volume production while maintaining strict quality control. Our skilled technicians utilize precision machining, injection molding, and assembly processes to produce magnet assemblies with exceptional precision and consistency. We adhere to rigorous quality management systems to ensure that every product leaving our facility meets the highest standards of excellence. Custom Solutions: In addition to our standard product offerings, we take pride in our ability to develop custom magnet assemblies to address unique application challenges. Our team of experts collaborates closely with customers to understand their specific requirements and develop tailored solutions. We leverage our vast knowledge and experience in magnet technology to design and manufacture custom solutions that deliver optimal performance and value. Industries Served: Magni-Power Company Magnetics Division serves a wide range of industries, including automotive, aerospace, electronics, medical devices, energy, telecommunications, and more. Our magnet assemblies find applications in motors, generators, sensors, speakers, magnetic separators, magnetic couplings, magnetic resonance imaging (MRI) machines, and various other electromechanical systems. Conclusion: As a leading provider of Magnet Assemblies, Magni-Power Company Magnetics Division is committed to delivering innovative, high-quality products and exceptional service to our customers. With our expertise, state-of-the-art facilities, and customer-centric approach, we are the go-to choice for companies seeking reliable and efficient magnet solutions.

Alloy Suppliers

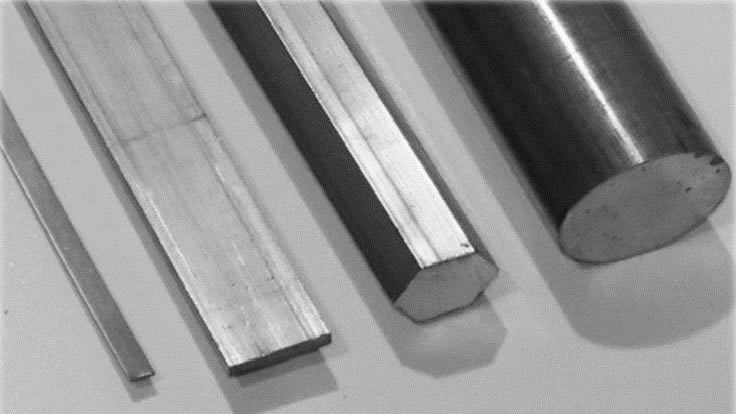

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

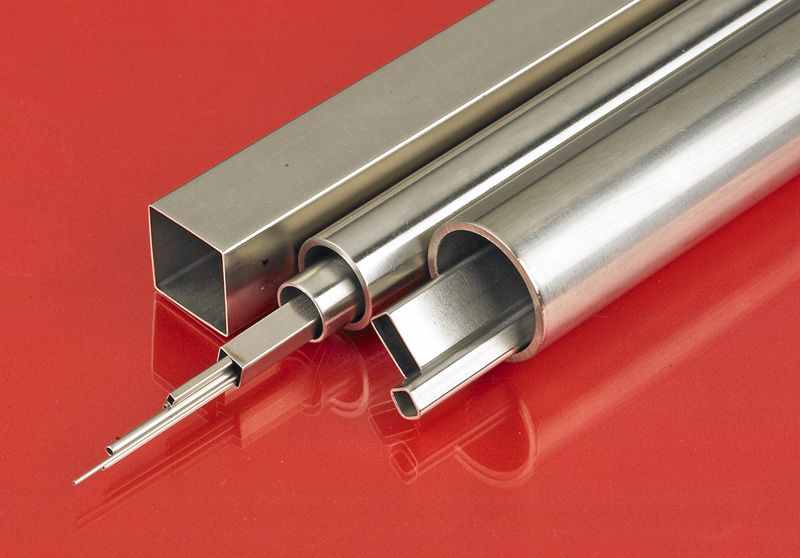

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

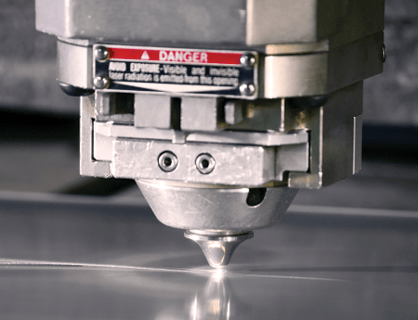

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services