Magnetic Lifting Technologies US

Magnetic Lifting Technologies US Request A Quote

New Castle, PAMagnetic Lifting Technologies US is a leading provider of innovative magnet assemblies and related services. With a strong commitment to quality, reliability, and customer satisfaction, we specialize in designing, manufacturing, and supplying a wide range of magnet assemblies for various industries and applications. Our Magnet Assemblies: At Magnetic Lifting Technologies US, we offer a diverse portfolio of magnet assemblies that are designed to meet the unique needs of our customers. Whether you require powerful magnetic solutions for lifting, separating, holding, or any other application, our magnet assemblies are engineered to deliver exceptional performance and durability. Our magnet assemblies are available in various configurations, including permanent magnets, electromagnets, and hybrid magnet systems. We utilize advanced materials and cutting-edge manufacturing techniques to ensure the highest quality and performance standards. Our team of experienced engineers works closely with our clients to understand their specific requirements and tailor solutions that best suit their needs. Service Capabilities: In addition to our exceptional magnet assemblies, Magnetic Lifting Technologies US offers a comprehensive range of service capabilities to support our customers throughout the entire product lifecycle. Our services include: 1. Custom Design and Engineering: Our skilled team of engineers collaborates closely with clients to develop custom magnet assemblies that precisely match their application requirements. We leverage advanced modeling and simulation tools to optimize designs and ensure optimal performance. 2. Prototyping and Testing: We provide rapid prototyping services to validate designs and ensure that they meet the desired specifications. Through rigorous testing and analysis, we verify the performance, reliability, and safety of our magnet assemblies before full-scale production. 3. Manufacturing and Production: Magnetic Lifting Technologies US operates state-of-the-art manufacturing facilities equipped with advanced machinery and quality control systems. Our production processes are designed to deliver high-quality magnet assemblies efficiently and in a timely manner, while adhering to stringent quality standards. 4. Installation and Training: We offer comprehensive installation support to ensure proper integration of our magnet assemblies into our customers' systems. Additionally, we provide training programs to educate users on the safe and effective operation of our magnet assemblies. 5. Maintenance and Support: We understand the importance of ongoing support and maintenance for our customers' operations. Our team provides technical assistance, troubleshooting, and maintenance services to ensure the longevity and optimal performance of our magnet assemblies. Industries Served: Magnetic Lifting Technologies US caters to a wide range of industries, including manufacturing, automotive, aerospace, electronics, renewable energy, mining, construction, and more. Our magnet assemblies find applications in material handling, magnetic separation, lifting and positioning, robotics, magnetic resonance imaging (MRI), and other critical processes. At Magnetic Lifting Technologies US, we are dedicated to exceeding our customers' expectations by delivering superior magnet assemblies and comprehensive services. With our technical expertise, commitment to innovation, and customer-centric approach, we strive to be the preferred partner for all magnet assembly needs.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

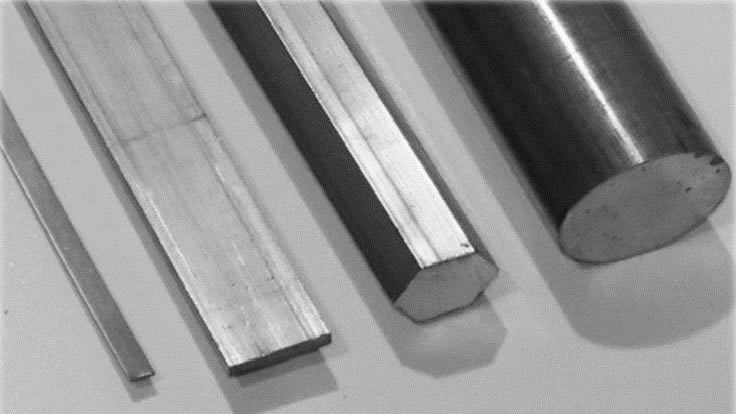

Nickel Stainless Steel

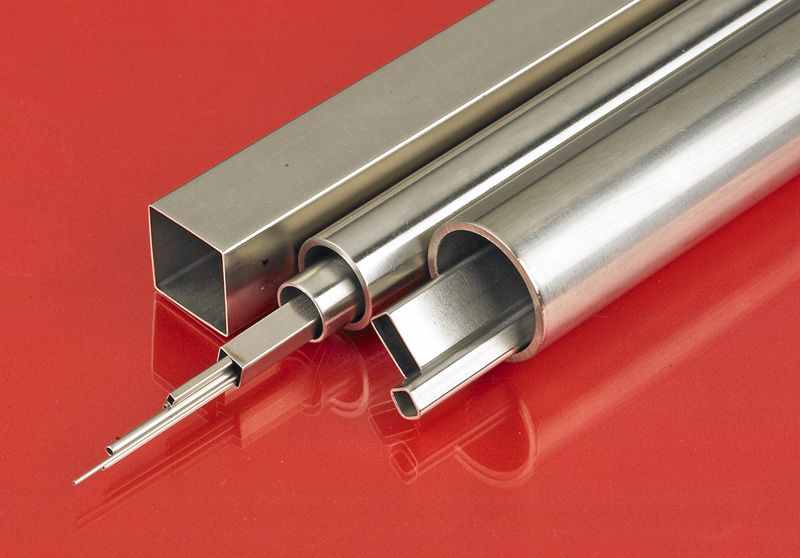

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

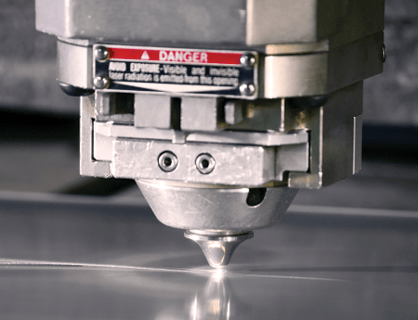

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services