Magnet Engineering

Magnet Engineering Request A Quote

Milford, OHMagnet Engineering is a leading provider of magnet assemblies and related services, catering to a wide range of industries and applications. With a strong commitment to innovation, quality, and customer satisfaction, we have established ourselves as a trusted partner in the magnetic solutions industry. Our Magnet Assemblies: At Magnet Engineering, we specialize in designing, manufacturing, and supplying high-quality magnet assemblies tailored to meet the specific needs of our customers. Our magnet assemblies are crafted using advanced materials and precise engineering techniques, ensuring optimal performance and durability. We offer a diverse range of magnet assemblies, including: 1. Permanent Magnet Assemblies: Our permanent magnet assemblies combine powerful magnets, such as neodymium (NdFeB) or samarium cobalt (SmCo), with various housing materials to create compact, efficient, and reliable solutions. These assemblies are widely used in motors, sensors, speakers, magnetic separators, and other applications. 2. Electromagnet Assemblies: Our electromagnet assemblies consist of coils wound around a ferromagnetic core, providing a controllable magnetic field when electric current flows through the coil. These assemblies are used in applications such as magnetic lifting, magnetic clamping, electromagnetic brakes, and solenoid valves. 3. Magnetic Assembly Systems: We also offer complete magnetic assembly systems that incorporate multiple magnets and other components to create complex magnetic structures. These systems are designed to deliver precise magnetic fields, enabling applications in magnetic resonance imaging (MRI), particle accelerators, magnetic levitation, and more. Service Capabilities: In addition to our magnet assemblies, Magnet Engineering offers a comprehensive range of services to support our customers throughout their projects. Our service capabilities include: 1. Custom Design and Engineering: Our experienced team of engineers works closely with customers to understand their unique requirements and develop tailored magnet assembly solutions. We utilize advanced design tools and simulation software to optimize performance, efficiency, and manufacturability. 2. Prototyping and Testing: We provide prototyping services to validate and refine magnet assembly designs. Our well-equipped testing facilities enable us to evaluate the performance, magnetic properties, and other parameters of the assemblies, ensuring they meet the desired specifications. 3. Manufacturing Excellence: With state-of-the-art manufacturing facilities, we have the capabilities to produce magnet assemblies in both small and large quantities. Our manufacturing processes adhere to stringent quality control measures, ensuring consistent performance and reliability. 4. Quality Assurance: At Magnet Engineering, quality is of utmost importance. We implement rigorous quality assurance procedures at every stage of the manufacturing process, from material selection to final assembly. Our commitment to quality ensures that our magnet assemblies meet or exceed industry standards. 5. Technical Support and Customer Service: Our dedicated team of technical experts provides ongoing support to customers, assisting them with any technical queries, application challenges, or customization requirements. We strive to build long-term partnerships with our customers by delivering exceptional service and support. Conclusion: Magnet Engineering is a trusted provider of magnet assemblies, offering a wide range of products and comprehensive service capabilities. Whether you require permanent magnet assemblies, electromagnet assemblies, or complete magnetic assembly systems, we have the expertise and resources to meet your needs. With a focus on innovation, quality, and customer satisfaction, we are committed to delivering magnetic solutions that empower your applications and drive success.

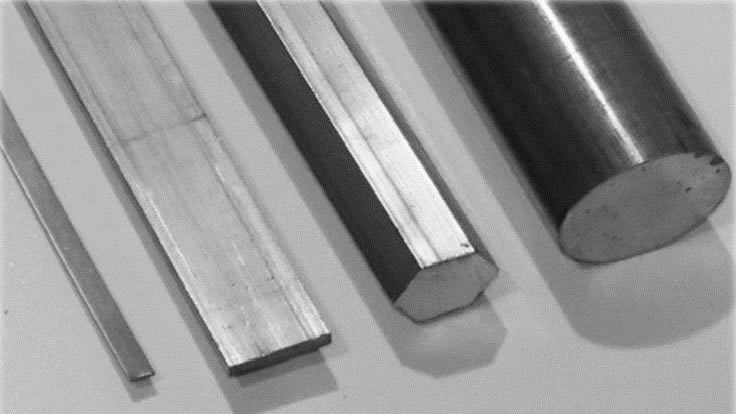

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

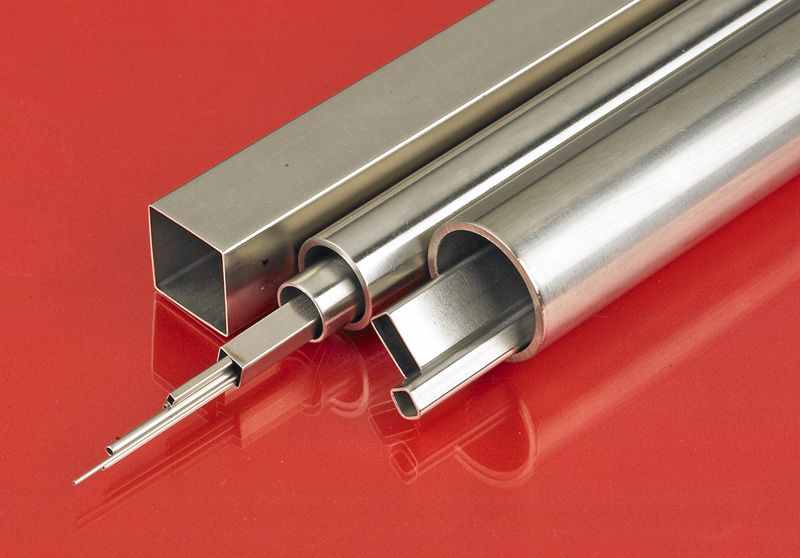

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

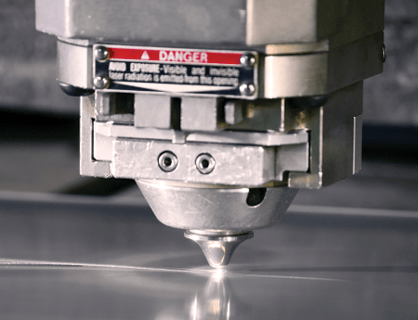

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services