Hitachi Metals America, LLC

Hitachi Metals America, LLC Request A Quote

Arlington Heights, ILHitachi Metals America, LLC (HMA) is a renowned leader in the field of advanced materials and components, offering innovative solutions for a wide range of industries. With a strong commitment to excellence, HMA continuously pushes the boundaries of technology to provide superior products and services to its global customers. As a subsidiary of Hitachi Metals Ltd., HMA leverages the extensive expertise and resources of its parent company, which has a rich history dating back over a century. With its headquarters in the United States, HMA serves as a key hub for Hitachi Metals' operations in North and South America. Product Focus: Magnet Assemblies HMA specializes in the design, development, and manufacturing of high-quality magnet assemblies. Magnet assemblies are critical components used in various applications, including automotive, aerospace, medical, energy, and industrial sectors. These assemblies play a pivotal role in enabling the efficient and reliable functioning of numerous devices, such as motors, generators, sensors, actuators, and magnetic resonance imaging (MRI) systems. HMA's magnet assemblies are meticulously engineered to meet the specific requirements and performance standards of each industry. By leveraging cutting-edge technologies, advanced materials, and precise manufacturing processes, the company delivers magnet assemblies that offer exceptional magnetic performance, durability, and reliability. Service Capabilities HMA offers a comprehensive range of services to support its customers throughout the entire lifecycle of their magnet assembly needs. These services include: 1. Design and Engineering: HMA's experienced team of engineers collaborates closely with customers to understand their unique requirements and challenges. Leveraging their expertise, they provide customized design solutions that optimize performance, efficiency, and cost-effectiveness. 2. Prototyping and Testing: HMA employs state-of-the-art prototyping facilities to quickly transform concepts into tangible prototypes. Through rigorous testing and analysis, the company ensures that the magnet assemblies meet or exceed the specified performance parameters. 3. Manufacturing Excellence: With world-class manufacturing facilities and processes, HMA maintains strict quality control measures to produce magnet assemblies of the highest standards. The company employs advanced fabrication techniques, precision machining, and assembly procedures to ensure consistent quality and reliability. 4. Supply Chain Management: HMA has established a robust global supply chain network, ensuring a reliable and timely supply of raw materials and components. This enables the company to meet customer demands efficiently while maintaining competitive pricing. 5. Technical Support and After-sales Service: HMA is committed to providing exceptional customer support throughout the product lifecycle. The company's technical experts offer assistance with installation, maintenance, troubleshooting, and optimization, ensuring customer satisfaction and long-term success. 6. Research and Development: HMA invests significantly in research and development to stay at the forefront of magnet assembly technology. Through continuous innovation, the company explores new materials, designs, and manufacturing techniques to enhance the performance and functionality of its products. Conclusion Hitachi Metals America, LLC (HMA) is a leading provider of advanced magnet assemblies, serving diverse industries with a commitment to innovation, quality, and customer satisfaction. With a comprehensive range of products and services, HMA enables its customers to harness the power of magnet assemblies and unlock new possibilities in their applications. Whether it's designing, manufacturing, or supporting magnet assemblies, HMA's expertise and capabilities make it a trusted partner for industries seeking cutting-edge solutions.

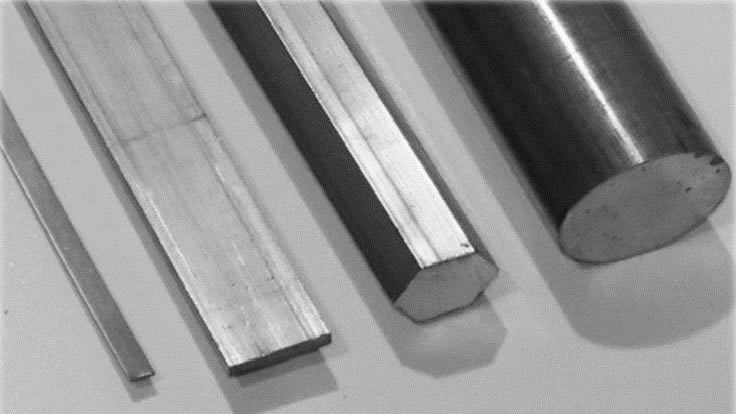

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

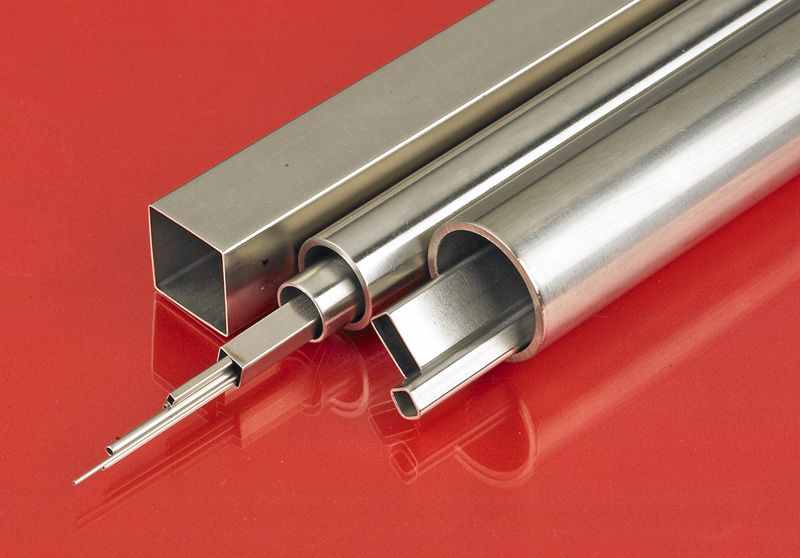

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

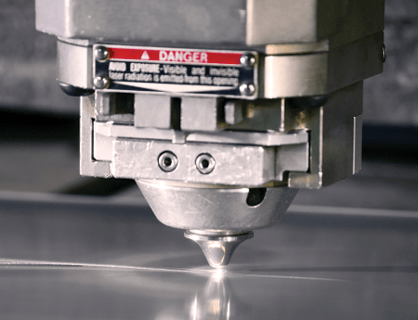

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services