Armstrong Magnetics Inc.

Armstrong Magnetics Inc.Request A Quote

Bellingham, WA | 800-965-4968Armstrong Magnetics Inc. is a leading provider of high-quality magnet assemblies and related services. With a rich history dating back over three decades, our company has earned a stellar reputation for delivering innovative and reliable magnetic solutions to a wide range of industries. At Armstrong Magnetics, we are committed to excellence in both product quality and customer service, making us the preferred choice for magnet assemblies worldwide. Magnet Assemblies: Our core expertise lies in the design, development, and production of magnet assemblies. We offer a diverse range of magnet assemblies that cater to various applications and industries. Whether you require standard magnet assemblies or custom solutions tailored to your specific requirements, we have the expertise and capabilities to deliver. Our magnet assemblies are manufactured using the highest-quality materials and adhere to stringent quality control measures, ensuring exceptional performance and durability. Our magnet assembly products include: 1. Magnetic Separators: We offer a comprehensive range of magnetic separators that are designed to efficiently separate ferrous contaminants from different materials. Our separators are widely used in industries such as mining, recycling, food processing, and pharmaceuticals, among others. 2. Magnetic Chucks: Our magnetic chucks are ideal for holding ferrous workpieces securely during machining, grinding, or inspection processes. We offer a variety of standard and custom magnetic chucks with different sizes and holding forces to meet specific customer needs. 3. Magnetic Lifters: Designed to simplify material handling operations, our magnetic lifters provide a safe and efficient solution for lifting and transporting ferrous materials. Our lifters are built to withstand heavy loads while ensuring maximum safety and reliability. 4. Magnetic Sweepers: We offer high-performance magnetic sweepers that effectively pick up metal debris, such as nails, screws, and other metallic objects, from various surfaces. These sweepers are widely used in construction sites, manufacturing facilities, and parking lots, among other environments. Service Capabilities: In addition to our comprehensive product portfolio, Armstrong Magnetics is renowned for its exceptional service capabilities. Our dedicated team of engineers and technical experts works closely with customers to understand their specific requirements and provide tailored solutions. We offer the following services to ensure customer satisfaction: 1. Custom Design and Engineering: Our experienced design and engineering team can collaborate with you to develop custom magnet assemblies that precisely meet your application requirements. We utilize advanced design software and simulation tools to optimize the performance and efficiency of the magnet assemblies. 2. Prototyping and Testing: We have state-of-the-art prototyping facilities to quickly transform concepts into tangible prototypes. Our rigorous testing procedures ensure that the magnet assemblies meet the highest quality standards and perform optimally in real-world conditions. 3. Manufacturing and Production: Armstrong Magnetics operates modern manufacturing facilities equipped with advanced machinery and production technologies. Our skilled workforce ensures the efficient and precise manufacturing of magnet assemblies while adhering to strict quality control protocols. 4. Technical Support and Maintenance: We provide comprehensive technical support to our customers, assisting them with installation, troubleshooting, and maintenance of our magnet assemblies. Our responsive customer service team is available to address any inquiries or concerns promptly. Industries Served: Armstrong Magnetics serves a diverse range of industries, including but not limited to: - Automotive - Aerospace - Electronics - Medical and healthcare - Mining and minerals - Food processing - Packaging - Construction - Renewable energy Conclusion: With our commitment to excellence, extensive product range, and unmatched service capabilities, Armstrong Magnetics Inc. is the trusted partner for magnet assemblies. We strive to exceed customer expectations by delivering superior quality products, innovative solutions, and exceptional customer service. Whether you require standard magnet assemblies or custom-designed solutions, Armstrong Magnetics is your reliable source for all your magnetic needs.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

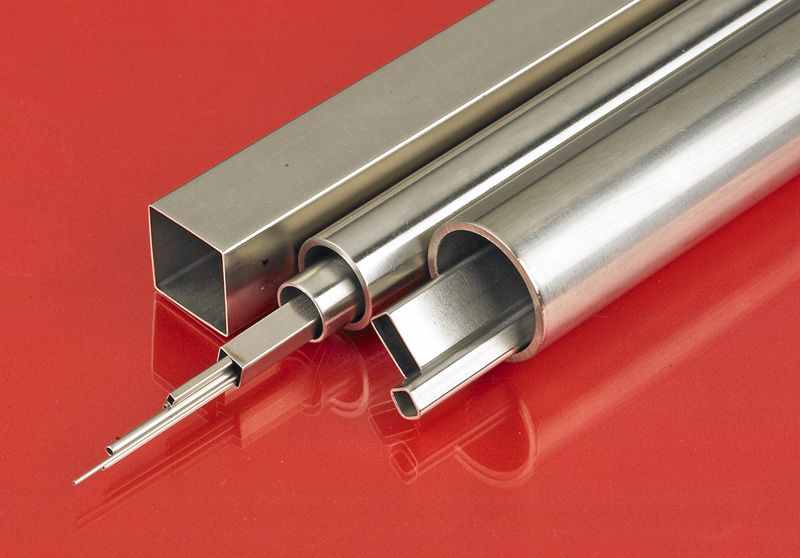

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

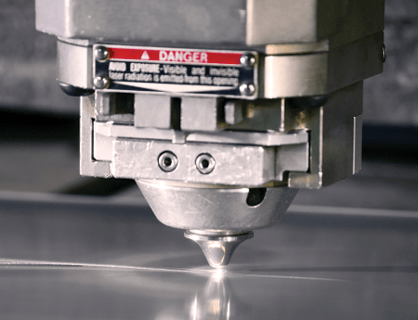

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

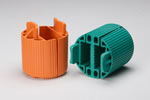

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services